On-Time Order Shipments & Delivery

2026 - WEEK 7; 100%

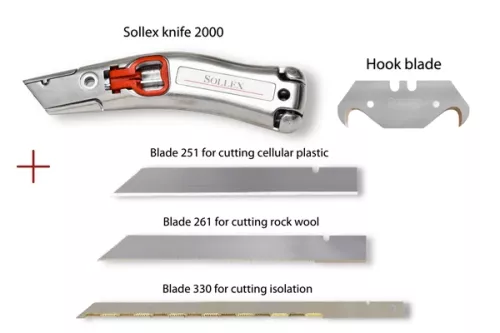

Sollex's robust universal and construction knives for professional craftsmen, handymen and carpenters are suitable to cut a variety of materials such as plasterboard, roofing felt and flooring materials.

The award-winning Sollex 2000 construction knife, when combined with PRO hook blades 10P, is highly favored by roofers and floorers. Together with the titanium coated utility blades of the PRO series, you get the most efficient and durable knife for cutting the most difficult materials.

We also have a wide range of trapezoidal blades in both standard and special sizes, as well as concave, crescent utility blades to cut tubes, mats and flexible building materials.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

A utility knife is a knife with a sharp, replaceable, and often retractable blade designed for cutting various materials, such as cardboard, drywall, corrugated packaging, plastic, and others. With its general-purpose design, compact size, and usually sturdy but ergonomic handle, the utility knife is a versatile tool.

A utility knife is a knife with a sharp, replaceable, and often retractable blade designed for cutting various materials, such as cardboard, drywall, corrugated packaging, plastic, and others. With its general-purpose design, compact size, and usually sturdy but ergonomic handle, the utility knife is a versatile tool.

The user can adjust the blade with the handle. Therefore, the utility knife serves a variety of purposes. For example, by advancing the blade up to 1 cm forward, it is possible to use the utility knife as a box cutter. You can use it to cut the tape of a box without causing any harm to its contents. When the blade becomes blunt, it can be quickly replaced, prolonging the knife's lifetime. The main thing is to always have a spare blade that fits your knife and the job at hand.

There are many types of utility knives that resemble each other in appearance. The main difference between utility knives is whether the blade is retractable or not and the type of blade that is placed in them. By replacing the blade, you can change the functionality of the knife. For example, by inserting a heavy-duty blade into a knife that is extra durable, thicker, and possibly coated, you will increase the knife's performance and can use it to cut particularly tough objects for a longer period of time.

Some knives lack a slider to extend the blade, which results in a more stable locking mechanism for the blade. Some utility knives have a screw that holds the body together and fixes the blade. Most utility knives have a blade storage compartment in their handles. It is also possible to find utility knives with folding handles. These knives are called folding knives.

Therefore, we can distinguish these types of knives:

Folding utility knife | Folding utility knives are knives with a trapezoidal blade that folds into a handle for easy storage and use. These knives are commonly used by workers in factories, warehouses, construction projects and other situations where a compact tool is needed. A folding utility knife can be used to mark cutting lines, trim various construction materials, as well as tape, cord, strapping, cardboard or other packaging material. The problem with these knives is that they are often difficult to open-close with one free hand |

Safety utility knife | The design of safe utility knives lowers the risk of cutting the user. They include utility knives with automatic blade retraction, knives with a rounded blade tip, and others. It can be said that almost every safety knife can be considered a safety utility knife. Visit our "Safety Knives" category with a huge selection of different knives and find the right safety knife for you |

Heavy-duty utility knife | Heavy-duty knives are characterized by a robust construction and a thicker, stronger installed blade. They are suitable for use in the construction industry, e.g. for cutting drywall, linoleum, carpets and other materials. We recommend looking at the Sollex 2000 universal and durable construction knife and the Sollex Heavy-duty blade Banzai.

|

Box Cutter Knife | Utility knives that are considered good for cutting boxes are called box cutters. These knives are mostly used by warehouse workers and shipping departments. They are designed to open sealed boxes without damaging the contents inside. Such knives often have a protection at the place where the blade leaves the handle, which allows only slightly exposing the blade. Great for cutting materials such as tape, film, corrugated cardboard, cardboard |

Snap-Off Utility Knife | These utility knives are sometimes called “wallpaper knives”. Blades go through the body of the knife and have segments. It is possible to extend the blade with a slider. When the edge of the tip get blunt, the blade segment can be snapped off. It is not advisable to extend the blade much forward and do heavy work, as there is a risk that the blade will snap off where the blade notches on the blade and this can cause injury to the user of the knife. These knives almost always come in bright colors such as orange, blue, and yellow. Visit our "Snap off Knives" category with a wide range of different knives and find the right snap off knife for your needs |

Utility knives are used mainly in construction, and therefore we can define their main areas of application as:

Utility knives, being multi-purpose tools, are suitable for all cutting operations. The blade must be replaced when it wears out.

There are several kinds of blades for utility knives: utility hook blade, trapezoidal short and long utility blades, utility snap off blade, utility long blades, utility serrated blades

At Sollex, we offer a universal utility knife 2000 to use as the 2-in-1 knife / all-around utility knife that goes well with the most standard utility, concave, hook blades, and long knife blades. The dimensions of the blades that fit perfectly in the knife are standard. The user can easily access the utility knife, which also comes with a holster to keep it by their side.

At Sollex, we offer a universal utility knife 2000 to use as the 2-in-1 knife / all-around utility knife that goes well with the most standard utility, concave, hook blades, and long knife blades. The dimensions of the blades that fit perfectly in the knife are standard. The user can easily access the utility knife, which also comes with a holster to keep it by their side.

The different types of blades on this knife are perfect for various tasks that require cutting or slicing through different materials. This includes tasks like cutting through felt, cardboard, rubber, or polystyrene foam insulation panels, among others. Changing blades goes effortlessly, and it takes less than 10 seconds.

The Sollex 2000 knife's handle accommodates a blade dispenser. The most important thing is that the blade sits stably in the knife Sollex 2000.

A small magnet is located where the blade is placed. The goal is to let the user always insert the blade correctly. When the knife closes, the blade becomes fixed. Among other things, it is the most versatile knife, which fits almost any utility blade, such as hook blade, straight utility blade, concave blade, long blade, etc.

The Stanley knife has a cast metal body and is available in both a retractable version and a fixed-blade version with no depth adjustment. There are several versions of the classic Stanley No. 99. The Stanley 199E fixed-blade knife model is widely used for construction work. This knife, like other utility knives, has a place in the handle for storing spare or used blades. We offer Stanley knives of models 99E and 199E.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.