How to Prevent Corrosion of Industrial Knives and Blades

Corrosion is one of the most common reasons industrial knives lose performance earlier than expected. Even high-quality tool steel and stainless steel can react to humidity, residues and airborne particles in production environments. When corrosion begins, the edge wears faster and the blade becomes unstable in the cut. This text explains why corrosion forms on machine knives and how correct handling, storage and coating extends blade lifetime.

The nature of metal corrosion

The breakdown of a metal surface due to environmental exposure is known as corrosion. During corrosion the surface layer of the metal reacts with moisture, oxygen, or chemical deposits. The reaction weakens the steel and shortens the lifetime of the product. When corroded blades are used for cutting materials such as plastic film, the result will often be visible defects in the finished product.

Correct storage of industrial blades therefore reduces production faults and unnecessary costs.

Corrosion can develop due to several factors, such as variations in the atomic crystal structure, chemical differences within the steel and physical influences from the surrounding environment. When the mechanism behind the corrosion is understood, it is possible to select steels and treatments that slow down or prevent the process.

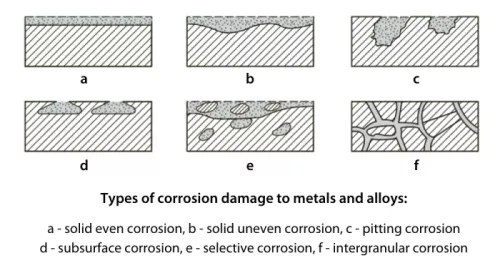

Metals and alloys can experience many forms of corrosion, including subsurface, selective, intergranular, pitting, even surface, and uneven surface corrosion. All of these forms involve gradual degradation of the metal surface. Some forms develop invisibly under the surface, while others are clearly visible. Industrial knives and blades are most often affected by selective corrosion.

Methods to protect industrial knives from corrosion

In practice, various effective methods have been developed to protect metal products from rusting. You will find them widely used in various industries and construction.

1. Packaging

Knives and blades are supplied in many shapes and sizes and therefore require different types of primary packaging. However several principles apply to all industrial blades.

1. Protective oils and greases are commonly used because they create a temporary barrier between the steel and the surrounding air. A thin film of anti corrosion oil prevents oxidation and protects the blade surface.

2. This oil layer alone is not enough. Machine knives are also wrapped in oiled, laminated or waxed paper for transport and short term storage. This prevents direct contact with moisture and condensation.

3. A vacuum is created around the blades to serve as the last line of defense. When the knives are stored under vacuum, oxidation processes are completely prevented, allowing for a significantly longer time until the box is opened.

Plastic dispensers are used in Sollex packaging for blades used in digital cutting machines. Every knife is separately vacuum packed as a sales unit, with its foam-tipped end fastened in the plastic dispenser.

2. Storage

Once you have opened the vacuum and primary packaging, it is important again to know some rules for storing industrial knives on your shelf.

- Put on gloves before handling a knife or blade. The blades are lubricated in the first place, and you won't leave fingerprints on their surface. When the thin layer of protective coating is broken, the area where the mark was left will eventually experience corrosion processes.

- Make sure all the knives and blades are uniformly oiled, securely wrapped in oiled paper, and kept in the box if they are in an open package and you won't be using them right away.

- Also, the air in the production department is often humid and warm, so avoid direct storage where production machines work. Maintain a regulated, low-humidity atmosphere in any spaces where blades are kept or utilized. Relative humidity should ideally be less than 50%. It is recommended to keep the temperature between 20 and 22°C (68 and 72°F).

- If you are using blades and knives that do not include an oil coating, it is important to keep the packaging tightly sealed and stored in a dry area. By keeping their blades well-oiled and protected from the air, users may stop their blades from rusting.

Industrial steel blades from Sollex are always supplied well-oiled and vacuum-sealed.

The above facts and tips do not apply to industrial solid tungsten carbide blades. Machine blades made of tungsten carbide do not need an oil coating because tungsten carbide material does not rust.

3. Coating of blades

Coating blades for industrial applications with various alloys is mainly done to improve their performance, wear resistance, hardness and blade sharpness. But blade coatings also protect the surface from corrosion.

Coating blades for industrial applications with various alloys is mainly done to improve their performance, wear resistance, hardness and blade sharpness. But blade coatings also protect the surface from corrosion.

In this article, you can read more about Sollex coatings for industrial machine knives and blades.

Which machine knife is right for my business?

Sollex has an expansive range of machine knives and razor blades for industrial applications. All the knives and blades we offer are tested by previous customers and are packed properly in industrial packaging. If you do not find what you are looking for, it is helpful to know that Sollex develops most of our machine knives together with customers.

If you have any questions about industrial machine knives and blades, please contact Sollex on +4635-15 75 00.

Buy your industrial knives and blades with high cutting edge performance online at Sollex.se

FAQ

Q: Why do industrial knives and blades corrode?

A: Corrosion forms when steel reacts with moisture, oxygen, chemicals, or residues in humid or contaminated environments, even on high-quality tool steel and stainless steel.

Q: How does corrosion affect cutting performance?

A: Corrosion weakens the cutting edge, increases wear, reduces edge stability, and often causes visible defects in the finished material.

Q: What is the best way to prevent corrosion on industrial blades?

A: Proper packaging, controlled storage conditions, protective oils, and suitable blade coatings are the most effective ways to prevent corrosion.

Q: Why are industrial knives supplied oiled and vacuum packed?

A: Protective oil creates a barrier against oxidation, while vacuum packaging removes air and moisture, preventing corrosion during transport and storage.

Q: How should industrial knives be stored after opening the package?

A: Blades should be handled with gloves, lightly oiled, wrapped in oiled paper, and stored in a dry environment with humidity below 50%.

Q: Can fingerprints cause corrosion on blades?

A: Yes. Fingerprints break the protective oil layer and introduce moisture and salts, which can lead to localized corrosion.

Q: Do tungsten carbide blades need corrosion protection?

A: No. Solid tungsten carbide blades do not rust and therefore do not require oiling or corrosion protection.

Q: Do blade coatings help prevent corrosion?

A: Yes. Coatings such as TiN or ceramic protect the blade surface from moisture and chemicals while also improving wear resistance and blade life.