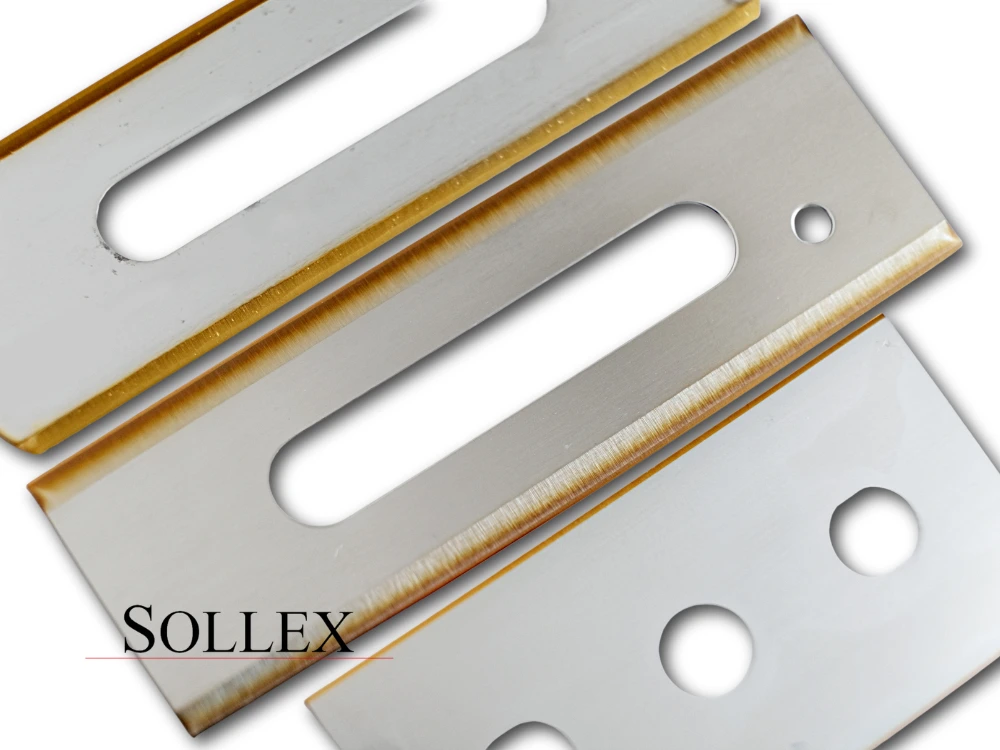

Sollex Titanium Nitride (TiN) Coated Blades

What is Titanium Nitride (TiN) coating on industrial blades? Titanium Nitride (TiN) is a thin, gold-colored ceramic coating applied to the cutting edge of industrial razor blades and knives using advanced PVD technology. It increases hardness, reduces friction, resists adhesive buildup, and extends blade life up to four times compared to uncoated steel. Sollex TiN-coated blades deliver cleaner cuts, lower downtime, and are fully food-safe for packaging and film converting applications.

Learn more about other types of industrial coatings in the articles: Ceramic Coating for Industrial Razor Blades and Zero-Friction Coating for Industrial Razor Blades.

Content:

- TiN-coated blades

- Performance benefits of TiN-coated blades

- Applications of TiN-coated blades

- Which materials are best cut with TiN-coated blades

- Why choose Sollex TiN-coated blades

- FAQs

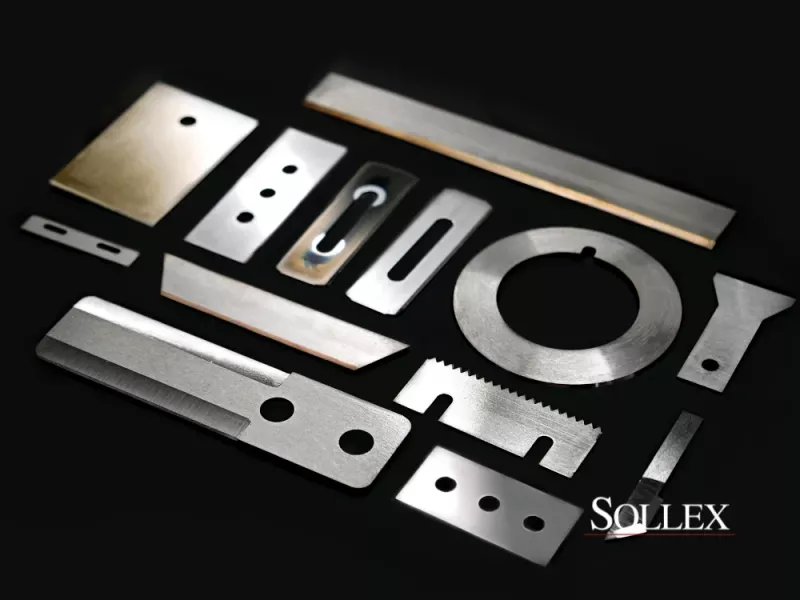

Which Sollex blade types are available with TiN coating?

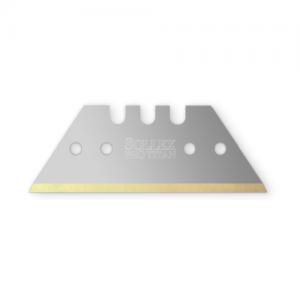

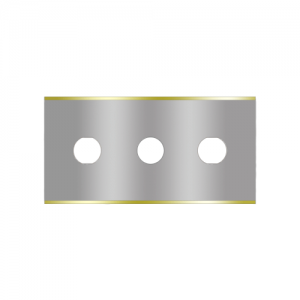

Have you ever noticed the distinctive golden shine on some converting industrial blades or their cutting edges that seem to keep cutting material shift after shift? That yellow color comes from titanium nitride TiN ( also known as tinite ), a special wear-resistant ceramic coating on the blade edge that extends the life of industrial tools. Sollex applies the TiN coating to its slitting knives, slotted razor blades, three-hole blades, injector blades, and custom-made machine knives, giving converters and packaging companies an easy way to reduce downtime while keeping cuts ultra-clean and food-safe.

All Sollex titanium-coated industrial knives and blades have “T” or “-T” in the article number.

Blade Type | Description |

|---|---|

For film and foil slitting in high-speed industrial machines | |

Standard in packaging and converting industries | |

Compact blades for precise and delicate cuts | |

Custom knives for automated or manual cutting equipment | |

Trapezoid-shaped / hook / concave / snap-off blades for utility knives |

Examples: 5T, 1-015-T, 2-020-T, 1-030-T, 9-065-T, 10PT, 9030-T, 16PT

Sollex Titanium Nitride coating is a thin, gold-colored layer applied using PVD (Physical Vapor Deposition) technology. This industrial coating provides a robust combination of hardness, thermal resistance, and low friction, making it ideal for coated razor blades and knives used in continuous production.

Feature | Value |

|---|---|

Color | Gold-yellow |

Maximum service temperature | 600 °C |

Hardness (HIT) | 30 GPa |

Intrinsic stress | –2 GPa |

Food-safe | Yes |

What are the performance benefits of TiN-coated blades?

Sollex blades with Titanium Nitride coating on the cutting blade edges enhances the blade’s resistance to both adhesive and abrasive wear, making it ideal for cutting demanding materials such as plastic films, laminates, foils, and adhesives.

Feature | Uncoated Steel Grade Blade | Sollex TiN-Coated Blade |

|---|---|---|

Wear resistance | Moderate | Excellent, coating protects edge |

Friction level | Higher, risk of material buildup | Lower, reduces sticking |

Blade life | Standard | Up to 4x longer |

Cutting precision | Degrades over time | Maintained over longer production runs |

Corrosion protection | None (carbon steel) or minimal (stainless steel) | High, coating forms a protective layer on the cutting edges |

Edge strength | More prone to chipping | Higher resistance to edge deformation |

Temperature resistance | Limited | Stable performance up to 600 °C |

Compatibility with food contact | Varies | Yes, food-safe coating |

Where are TiN-coated blades used in industrial cutting?

The use of Sollex TiN-coated blades leads to more stable production processes, cleaner cuts, and lower tooling costs over time. Whether in packaging, plastics, or industrial converting, the coating ensures blades stay sharper and more reliable.

Industry | Use Case Example | Why TiN Coating Matters |

Plastic film converting | Slitting polyethylene, polypropylene, barrier films | Reduces friction and extends blade life |

Adhesive tape production | Cutting materials with sticky layers | Prevents buildup, clean cuts |

Food processing & wrapping | Film and foil slitting, often in contact with food | Food-safe, clean edges, no contamination risk |

Laminates & multilayer films | Cutting through composite plastic structures | Coating protects edge against abrasive wear |

Nonwoven & textile processing | Cutting dense or layered synthetic materials | Increases edge durability, resists snagging |

Sollex TiN-coated blades are engineered for industrial environments where standard blades wear out too quickly or struggle with heat, adhesives, or buildup. These coated blades deliver the best results when cutting difficult materials or operating under continuous production conditions.

Which materials are best cut with TiN-coated blades?

Material Type | Example Products | Blade Type Commonly Used |

|---|---|---|

Plastic films | PE, PP, PET, PVC, PIR, multilayer films | Slotted or three-hole blades |

Foils and laminates | Aluminum, paper/foil composites | Slotted blades, injector blades |

Adhesive-backed substrates | Labelstock, protective films | Three-hole blades |

Flexible packaging materials | Food wraps, sachets, multilayer film | Machine knives |

Nonwoven or fibrous materials | Technical textiles, hygiene products | Injector blades, machine knives |

Construction materials | Roofing felt, linoleum, carpet, reinforced rubber, vinyl, adhesive material | Utility blades |

These blades are especially effective in continuous and automated production, where reduced blade changes and minimal machine stoppages translate directly into improved efficiency and profitability.

Why Choose Sollex TiN-Coated Blades

TiN-coated blades combine durability, precision, and food safety in one proven coating technology. By choosing Sollex TiN-coated blades, converters and packaging companies reduce blade changes, improve edge quality, and extend production runs. Contact Sollex to order standard or custom TiN-coated blades tailored to your application.

Feature | Sollex TiN-Coated Blades |

Coating consistency | Uniform layer thickness, no flaking |

Dimensional precision | Guaranteed blade geometry for high-speed cutting |

Application-specific optimization | Coating tailored for friction, heat, or wear resistance |

Quality control | Batch-tested for coating adhesion and hardness |

Custom solutions | Coated blades available in standard or custom shapes |

Customers across Europe rely on Sollex TiN-coated blades to improve output quality and reduce tooling wear in demanding industrial processes. The gold-yellow finish is more than visual; it signals performance that holds up under pressure. Whether you work with slotted, three-hole, injector blades or machine knives, Sollex TiN-coated blades offer the performance edge you need for modern industrial applications. Contact us at order@sollex.se for more information.

FAQ

Q: What is Titanium Nitride (TiN) coating on industrial blades?

A: Titanium Nitride (TiN) is a thin, gold-colored ceramic coating applied by PVD technology that increases blade hardness, reduces friction, and significantly extends blade life.

Q: What are the main benefits of TiN-coated razor blades?

A: TiN-coated blades offer lower friction, reduced adhesive buildup, higher wear resistance, cleaner cuts, and up to four times longer service life compared to uncoated steel blades.

Q: Are TiN-coated blades food-safe?

A: Yes. Sollex TiN-coated blades are approved for food contact and are widely used in packaging, film converting, and food-wrapping applications.

Q: Which Sollex blade types are available with TiN coating?

A: TiN coating is available on Sollex slotted slitter blades, three-hole razor blades, injector blades, utility blades, and custom-made machine knives.

Q: Which materials are best cut with TiN-coated blades?

A: TiN-coated blades perform best when cutting plastic films, foils, laminates, adhesive-backed materials, flexible packaging films, nonwovens, and technical textiles.

Q: How does TiN coating reduce downtime in production?

A: By minimizing wear, heat buildup, and material sticking, TiN-coated blades require fewer blade changes and enable longer, more stable production runs.

Q: What is the temperature resistance of TiN-coated blades?

A: Sollex TiN-coated blades maintain stable cutting performance at temperatures up to 600 °C.

Q: How can I identify a Sollex TiN-coated blade?

A: All Sollex TiN-coated blades have a gold-colored cutting edge and include a “T” or “-T” in the article number.

Q: Where can I order TiN-coated industrial blades?

A: Sollex supplies standard and custom TiN-coated blades with fast delivery. Orders and technical support are available via order@sollex.se.