Zero-Friction Coating for Industrial Razor Blades and Machine Knives

This article is part of the Sollex series on different industrial blade coatings. Each coating type has unique properties that solve specific challenges in film slitting and converting. In previous articles, we introduced the advantages of Titanium Nitride (–T) coating, which adds hardness and durability, and Ceramic (–K) coating, which provides superior wear resistance against abrasive fillers. In this article, we focus on the Zero-Friction (–Z) coating. Unlike TiN or Ceramic, this coating is designed to minimize drag, prevent sticking, and keep blades cool during high-speed cutting. It is the go-to solution for thin stretch films, sticky adhesive films, foils, and other elastic or clingy materials.

Content:

- About Zero-Friction

- How Zero-Friction coating works

- What changes to expect

- Technical information

- Applications, materials

- Customer cases

- Comparison with coatings

- Choose the right Zero-Friction blade

- FAQs

What Zero-Friction Coating Is

Sollex Zero-Friction (-Z) is a high-performance industrial-type coating applied to the cutting edge of industrial razor blades and machine knives. The coating creates an ultra-smooth, light grey surface layer with a very fine structure. Its main function is to provide extremely low friction. By minimizing drag at the blade-material interface, Zero-Friction allows film or foil to glide cleanly across the edge without sticking, tearing, or heating up.

Sollex Zero-Friction (-Z) is a high-performance industrial-type coating applied to the cutting edge of industrial razor blades and machine knives. The coating creates an ultra-smooth, light grey surface layer with a very fine structure. Its main function is to provide extremely low friction. By minimizing drag at the blade-material interface, Zero-Friction allows film or foil to glide cleanly across the edge without sticking, tearing, or heating up.

The coating also has the advantage of being safe for sensitive applications: Sollex Z-blades are FDA and EC approved, which means they can be used in food packaging production as well as in technical converting lines.

How the Zero-Friction Coating Works

In many cutting applications, friction poses a greater problem than blade wear. When thin plastic film, foil, or adhesive material comes into contact with the blade, the drag can generate heat, static, and edge buildup.p. A standard uncoated blade quickly clogs, overheats, and produces dust. By contrast, the Zero-Friction coating provides an almost lubricating effect on the cutting edge. The blade stays cooler, the film does not stick, and the cut remains stable even at very high speeds.

Compared to competitor blades with uneven or thin coatings, Sollex Z-blades show a clearly superior edge structure. Under 50× magnification, low-quality coatings reveal honeycombed edges and clusters of surface peaks that ruin cutting precision. Sollex 5Z blade, by contrast, has a thicker, more even coating and a razor-sharp straight edge, giving consistent slitting quality and long durability.

What Changes in Your Process

Switching to Sollex Z-coated blades is often felt immediately in production. Slitting becomes smoother and steadier. Operators see less dust around the slitting zone, fewer particles jumping onto adhesive films, and fewer interventions needed to keep slit width stable. For thin stretch films, the coating prevents the edge from heating up and melting the material, which means rolls wind more cleanly and production runs longer between blade changes.

Switching to Sollex Z-coated blades is often felt immediately in production. Slitting becomes smoother and steadier. Operators see less dust around the slitting zone, fewer particles jumping onto adhesive films, and fewer interventions needed to keep slit width stable. For thin stretch films, the coating prevents the edge from heating up and melting the material, which means rolls wind more cleanly and production runs longer between blade changes.

In adhesive film production, where static electricity makes particles “jump” onto the web, Zero-Friction blades minimize fines at the source. This reduces the risk of spoiled rolls and often eliminates the need for particle-removing rollers altogether.

Technical Information about Sollex Zero-Friction Coating

- Coating type: ultra-smooth light grey surface

- Friction coefficient: extremely low, optimized for thin and clingy films

- Function: prevents drag, sticking, and dust generation during slitting

- Food contact: FDA & EC compliant

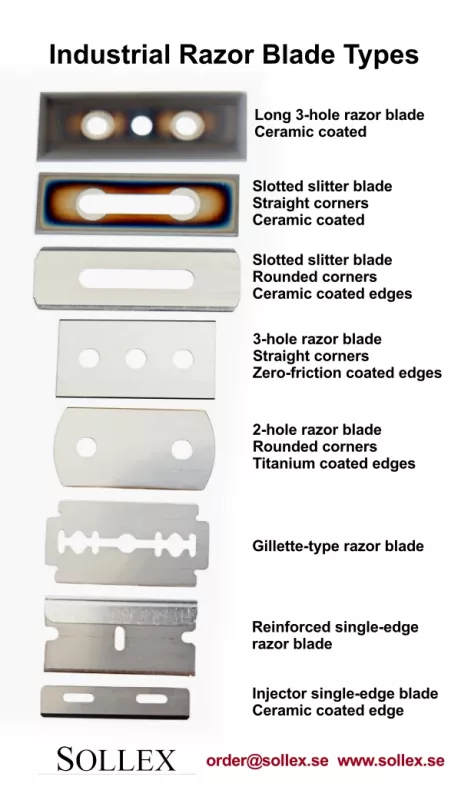

- Availability: edge-coated Sollex blades marked with “-Z” (slotted, 3-hole, injector, etc.)

Applications and Materials Best for Zero-Friction

Zero-Friction coated blades are developed for slitting materials where drag and sticking are the main issues. These include LLDPE and LDPE stretch films, pallet wrap, agricultural and construction films, adhesive protective films, nonwoven filter materials, aluminium foil, metallized films, and other thin, clingy substrates.

Zero-Friction coated blades are developed for slitting materials where drag and sticking are the main issues. These include LLDPE and LDPE stretch films, pallet wrap, agricultural and construction films, adhesive protective films, nonwoven filter materials, aluminium foil, metallized films, and other thin, clingy substrates.

For films filled with chalk, titanium dioxide, or other abrasive additives, the ceramic (-K) coating is usually more effective. For general plastic films without fillers, titanium nitride (-T) blades are often preferred. Still, in some cases, tests have shown that Z-blades produce less dust than TiN when slitting mineral-filled films.

Where Zero-Friction Wins - Customer Cases

Customer Case 1. Stretch Film at High Speed

A producer of pallet stretch film tested a competitor’s coated blade and found it dulled within 30 seconds. When replaced with a Sollex 5Z, the blade lasted seven days of continuous production while keeping a stable slit and clean cut.

Customer Case 2. Maximum Lifetime with Precision Blade

In another facility, thin stretch film was converted using the 4-60-030-Z blade. Thanks to its tight tolerances and Zero-Friction coating, the blade maintained excellent performance for six weeks before replacement, a huge gain compared to standard alternatives.

Customer Case 3. Adhesive Film and Dust Reduction

A manufacturer of sticky protective film struggled with particles jumping onto the film due to static electricity. By switching to Sollex Zero-Friction blades, the process generated virtually no dust or fines. This eliminated the need for particle-removing rollers and reduced scrap, improving both quality and cost-efficiency.

Customer Case 4. Thin PE and PP Films (20-25 µm)

A converter producing thin polyethylene and polypropylene films had problems with uneven roll edges and edge buildup. By introducing Sollex Z-coated 3-hole blades in 0.13 mm, 0.20 mm, and 0.30 mm thicknesses, the process stabilized. The blades minimized dust and ensured clean edges suitable for metallization in downstream processing.

Customer Case 5. Stretch Film in Rewinders

On stretch film rewinders, where slitting speed is more controlled, Sollex Z-coated blades such as 5Z and 4-60-030-Z were shown to deliver cleaner cuts and lower dust formation than uncoated or non-optimized blades. This avoided downstream handling issues and kept the rolls consistent.

Customer Case 6. Injector Blades for High-Speed Slitting

In the high-speed conversion of thin plastic films, Zero-Friction injector blades (642Z) performed up to three times longer than standard uncoated injectors. Customers highlighted that the Z-coating minimized plastic adhesion to both the edge and sides of the blade, making these injectors the best choice for cutting thin films as cleanly as possible.

Comparison with Other Sollex Coatings

Zero-Friction is one of 3 main Sollex coatings, each designed for different cutting challenges. Titanium nitride (-T) emphasizes hardness and durability for general films. Ceramic (-K) delivers abrasion resistance against mineral-filled films. Zero-Friction (-Z) is the specialist solution for thin, elastic, and sticky films, where drag and heat are the biggest obstacles.

Coating type | Best suited for | Main advantage | Service life vs uncoated* |

|---|---|---|---|

TiN (-T) | General films without fillers | High hardness, longer durability | 3-5× |

Ceramic (-K) | White films with chalk, filled PP, laminates | Abrasion resistance, clean cuts | 5-8× |

Zero-Friction (-Z) | Thin stretch and sticky films, foils, nonwoven | Extremely low drag, cool cutting | Weeks instead of hours |

*Based on customer results under comparable production conditions.

Choosing the Right Zero-Friction Blade

Different cutting environments require different blade thicknesses and geometries. For very thin stretch film at high speeds, Sollex offers Z-coated blades in 0.13, 0.20 and 0.30 mm thicknesses (2-013-Z, 2-020-Z, 2-030-Z). For greater stability, the 0.38 mm slotted 5Z blade is widely used. For the highest precision and longest lifetime, converters rely on the 4-60-030-Z, which combines extremely tight tolerances with the Zero-Friction coating. All Sollex Z-blades are manufactured from fine-grain stainless steel to ensure consistent quality and secure adhesion of the coating.

Art.item | Name | Dimensions | Coating |

|---|---|---|---|

Industrial razor blades for slitter rewinders / converting machinery | |||

3-hole razor blade 0.13mm | 43x22x0.13mm | Zero-Friction coated edge | |

3-hole razor blade 0.20mm | 43x22x0.20mm | Zero-Friction coated edge | |

3-hole razor blade 0.30mm | 43x22x0.30mm | Zero-Friction coated edge | |

Rounded 3-hole razor blade 0.13mm | 43x22x0.13mm | Zero-Friction coated edge | |

Long 3-hole razor blade 0.30mm | 60x22x0.30mm | Zero-Friction coated edge | |

Rounded slotted razor blade 0.38mm | 57.2x18.7x0.38mm | Zero-Friction coated edge | |

Straight slotted razor blade 0.40mm | 57x18.8x0.40mm | Zero-Friction coated edge | |

Straight slotted razor blade 0.20mm | 59x18.8x0.20mm | Zero-Friction coated edge | |

Injector razor blade | 38x8x0.25mm | Zero-Friction coated edge | |

Injector razor blade Martor 789 | 80x8x0.25mm | Zero-Friction coated edge | |

Conclusion

Sollex Zero-Friction blades are the coating of choice when cutting thin, elastic or sticky films. By drastically reducing drag, they ensure smoother slitting, cooler operation, and longer uninterrupted runs. With proven results in customer production (from stretch films to adhesive protective films) Z-coated blades deliver measurable gains in uptime and quality. Look for the “-Z” in the Sollex article number to select the right Zero-Friction solution for your cutting process.

FAQ

Q: What is Sollex Zero-Friction (-Z) coating?

A: It is a PVD-applied edge coating with an ultra-smooth grey surface that drastically reduces friction between the blade and the material, ensuring cooler cutting and smoother slitting.

Q: Which materials are best cut with Zero-Friction blades?

A: Zero-Friction blades are ideal for thin stretch films (LLDPE, LDPE), pallet wrap, sticky protective films, adhesive films, aluminium foil, metallized film, nonwoven filter materials, and other clingy or elastic substrates.

Q: How does Zero-Friction compare to Ceramic (-K) or Titanium Nitride (-T) coatings?

A: TiN (-T) emphasizes hardness for general films, Ceramic (-K) excels against abrasive fillers like chalk, while Zero-Friction (-Z) is the specialist choice for thin and sticky films where drag and heat are the biggest issues.

Q: How much longer do Zero-Friction blades last compared to uncoated blades?

A: In thin stretch film production, uncoated blades may last only minutes or hours. Sollex Zero-Friction blades have been proven in customer production to last days or even weeks, depending on the setup.

Q: Can Zero-Friction blades reduce dust and particles in adhesive film cutting?

A: Yes. Because the coating minimizes friction and prevents edge buildup, Z-blades produce significantly fewer fines. Customers report reduced static-related dust and in many cases could eliminate particle-removing rollers.

Q: What blade formats are available with Zero-Friction coating?

A: Sollex offers Zero-Friction coating on slotted blades (5Z), 3-hole blades (2-013-Z, 2-020-Z, 2-030-Z), high-precision designs (4-60-030-Z), and injector blades (642Z). All are manufactured from fine-grain stainless steel with consistent coating quality.

Q: Are Sollex Zero-Friction blades safe for food packaging?

A: Yes. Like all Sollex coatings, Zero-Friction is FDA and EC approved, making it suitable for food contact applications.