Ceramic Coating for Industrial Razor Blades and Machine Knives

What is ceramic coating on industrial razor blades and machine knives? Ceramic coating is a thin, ultra-hard layer applied to the edge or entire surface of a blade. It reduces friction, resists adhesive buildup, and protects against abrasive fillers. In practice, a Sollex ceramic-coated blade can last up to 5-8 times longer than an uncoated blade when slitting plastic films, foils, or laminates. This makes ceramic coating one of the most effective ways to lower downtime, improve cut quality, and reduce cost-per-meter in film converting and packaging production.

Learn more about other types of industrial coatings in the articles: Sollex Titanium Nitride (TiN) Coated Blades and Zero-Friction Coating for Industrial Razor Blades.

Content:

- How industrial coatings work

- Technical information

- Edge-coated “K” vs full-ceramic “X”

- Real customer cases

- What improvements to expect

- How to choose the right coating

- List of Sollex ceramic-coated blades

- FAQs

How the coating on the industrial blades works

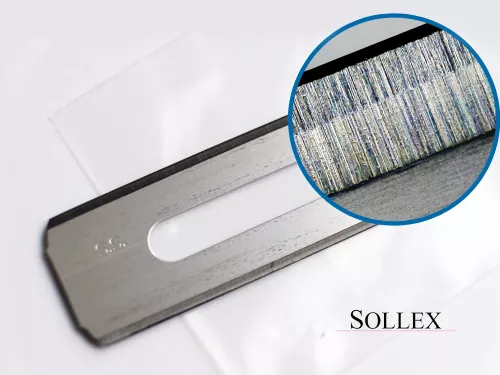

When we say ceramic coating on a Sollex blade, we mean a thin industrial-type coating layer on the steel blade. Sollex ceramic coating behaves like a dry-lubricating skin on the cutting edge. It’s hard enough to resist adhesive wear and galling, yet slick enough to lower friction at the blade-film interface. In practice, this coating provides a sharp edge that remains clean rather than accumulating fines, inks, or adhesive dust. The film glides over the edge instead of fighting it. Thermal stability is ample for converting: the coating remains effective at the temperatures you reach in high-speed slitting, and it adds a measure of corrosion and oxidation protection to the steel underneath.

When we say ceramic coating on a Sollex blade, we mean a thin industrial-type coating layer on the steel blade. Sollex ceramic coating behaves like a dry-lubricating skin on the cutting edge. It’s hard enough to resist adhesive wear and galling, yet slick enough to lower friction at the blade-film interface. In practice, this coating provides a sharp edge that remains clean rather than accumulating fines, inks, or adhesive dust. The film glides over the edge instead of fighting it. Thermal stability is ample for converting: the coating remains effective at the temperatures you reach in high-speed slitting, and it adds a measure of corrosion and oxidation protection to the steel underneath.

Read more about industrial coatings and their benefits in our blog post: "Guide to Knife & Blade Coatings".

What ceramic coating changes in cutting process

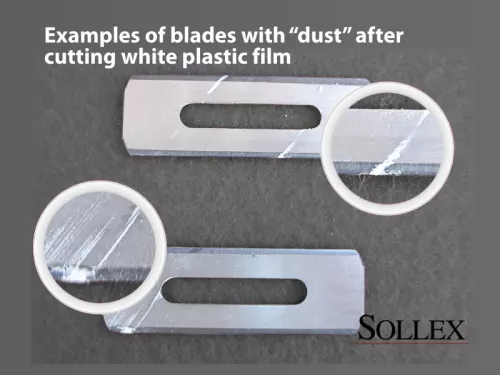

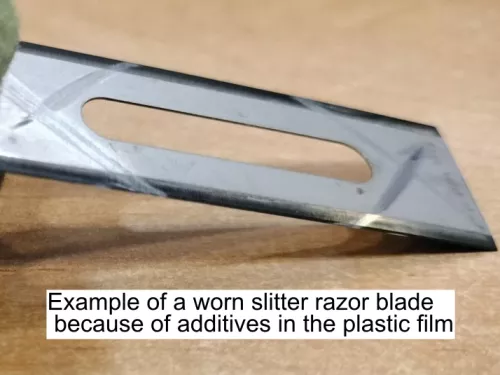

If you slit filled or “white” films, you know the drill: abrasive masterbatches CaCO₃or TiO₂ chew through uncoated edges, dust rises, cut quality drifts, and you stop to change slitter blades. A ceramic-coated Sollex knife cuts cooler and cleaner, so the edge doesn’t seize or smear. That means less dust, fewer stops, and steadier web tension because the edge condition is stable for longer. On printed or laminated materials, the smoother edge of the blade helps prevent ink or glue from sticking to it, keeping the cut sharp and preventing dirt from getting into the web path.

Technical Information about Sollex Ceramic Coating

- Coating type: ceramic-like carbon with tungsten carbide

- Coating thickness: 1-4 μm (depending on blade type)

- Performance: up to 5-8× longer lifetime than uncoated blades in abrasive conditions

- Effect on cut: lower friction, cleaner edges, less dust formation

- Resistance: strong protection against adhesive wear, galling, corrosion, and oxidation

- Approval: FDA & EC compliant for food contact

- Available formats: edge-coated (-K) and fully coated (-X), in standard Sollex geometries (slotted, 3-hole, rounded or square corners)

Sollex ceramic-coated slitting knives and blades are approved for food contact (FDA and EC), which is why they are heavily used on packaging lines. You’ll find K-marked options across our standard geometries and thicknesses, from thin 0.10 mm 3-hole blades for the cleanest cut to robust 0.38 mm slotted blades when stiffness and impact tolerance matter. Fully coated X versions are available where full-surface protection is the right answer.

Edge-coated “K” vs full-ceramic “X”

Sollex marks ceramic options clearly:

- K-series (e.g., 5K, 1-020-K): ceramic on the edge. It's the best general choice when you want long life and low friction without changing blade geometry or stiffness.

- X-series (e.g., 5X, 2-020-X): fully ceramic-coated blade surfaces. Choose this when materials are particularly “dirty” (heavy fillers, inks, adhesives) or when you want maximum resistance to pickup across the whole blade.

Both options are stocked in common formats (slotted razor blades with rounded or square corners, three-hole blades, etc.) so you can match the coating to your holders and cut geometry without retooling.

Where ceramic coating wins (Real Customer Cases)

Case 1. White film with chalk (CaCO₃)

A film extruder slitting “white” PE with high CaCO₃ content struggled with rapid dulling and chalk dust around the slit. Switching from uncoated to 5K cut the dust noticeably and stretched blade life from days to roughly a one-to-two-week run window, holding slit width and edge quality more consistently. Maintenance reported fewer tension adjustments because cut resistance stayed stable rather than creeping up mid-run.

_

Case 2. PP that behaves “rubbery” with filler

A converter running PP with CaCO₃ masterbatch saw occasional snags and early micro-chipping on standard edges. Ceramic 5K delivered longer steady-state cutting; where the film behaved very rubber-like at certain gauges, they kept 5V in rotation for specific SKUs, and used 5Z when they moved similar structures onto a high-speed line. In other words: K is the dependable base case for filled PP; V or Z gets deployed for edge cases of material behavior or line speed.

_

Case 3. Printed laminate with adhesive

On a printed PET/PE laminate, the uncoated edge gradually picked up ink and adhesive fines, making the cut scratchy and causing periodic web cleaning. Moving to 5X (full ceramic) reduced pickup on the bevel and flanks. The result was a cleaner edge over a longer run, fewer wipe-downs, and far less risk of particles migrating downstream.

On a printed PET/PE laminate, the uncoated edge gradually picked up ink and adhesive fines, making the cut scratchy and causing periodic web cleaning. Moving to 5X (full ceramic) reduced pickup on the bevel and flanks. The result was a cleaner edge over a longer run, fewer wipe-downs, and far less risk of particles migrating downstream.

_

Case 4. Stretch film at speed

For thin LLDPE stretch film on very high line speeds, Z-coated remains the first pick due to extreme drag reduction. But for high-speed white or lightly filled stretch variants, K-coated blades often prove the better balance: still low friction, but with superior resistance to the abrasive wear that Z alone doesn’t address.

_

Case 5. Plastic-paper composites

In plastic-paper mixes, the ceramic surface resists fiber scuffing and reduces lint on the edge. Plants reported cleaner knife boxes and fewer web specks after switching to K-series blades.

What improvements you can expect after you start using Sollex ceramic-coated blades

Operators notice two things very quickly: the cut sounds smoother, and the slit stays clean. Engineers see it in the data: longer mean time between blade changes, lower current draw on driven slitters (less cutting resistance), and steadier slit width over the roll. Quality teams see fewer edge-defect complaints and lower particle counts around the cutting zone. Finance sees the uptime.

How to choose the right coating for industrial cutting knives

If your material includes mineral fillers, ink, or adhesive, start with a K-series edge-coated blade. If your job runs are long, the web is printed or adhesive-rich, or contamination on blade flanks has been a persistent pain, step up to X-series full ceramic. For thin, fast, virgin stretch, Z stays the first choice; for filled films, K is the safer play. For unusually rubber-like PP, test V alongside K and pick the most stable slit over the full run length.

Coating / Blade type | Typical materials | Key advantage in production | Customer experience |

|---|---|---|---|

Uncoated | Virgin PE, PET, HDPE without fillers | Lowest cost, sharp but short-lived | Lasts only a few days, frequent stops |

General plastic films without heavy fillers | Very hard edge, longer life | Clean cuts, good durability but sensitive to fillers | |

Ceramic edge-coated (-K) | White PE with CaCO₃, PP with filler, laminates, stretch/shrink films | Low friction, resists abrasive wear | Extends life from days to 1–2 weeks, less dust |

Full ceramic (-X) | Films with heavy additives, printed laminates, adhesive-rich webs | Maximum coating coverage, reduced pickup | Cleaner bevel, fewer wipe-downs, longer steady runs |

Thin LLDPE stretch films, high-speed slitting | Minimal drag, very smooth running | Ideal for speed, but less resistant to abrasive fillers | |

V-series | Rubber-like PP with high filler content | Strong edge for tough, elastic films | Reliable slit where K struggles |

Buy ceramic-coated machine knives & slitter blades

Customers across Europe rely on Sollex ceramic-coated blades to improve output quality and reduce tooling wear in demanding industrial processes. The dark greyish finish signals performance that holds up under pressure. Whether you work with slotted, 3-hole, injector blades or machine knives, Sollex ceramic-coated blades offer the performance edge you need for modern industrial applications.

Art.item | Name | Dimensions | Coating |

|---|---|---|---|

Industrial razor blades for slitter rewinders / converting machinery | |||

3-hole razor blade 0.13mm | 43x22x0.13mm | Ceramic-coated cutting edge | |

3-hole razor blade 0.20mm | 43x22x0.20mm | Ceramic-coated cutting edge | |

3-hole razor blade 0.30mm | 43x22x0.30mm | Ceramic-coated cutting edge | |

3-hole razor blade 0.13mm | 43x22x0.13mm | Fully coated with ceramic | |

3-hole razor blade 0.20mm | 43x22x0.20mm | Fully coated with ceramic | |

3-hole razor blade 0.30mm | 43x22x0.30mm | Fully coated with ceramic | |

Rounded 2-hole razor blade 0.13mm | 43x22x0.13mm | Ceramic-coated cutting edge | |

Rounded 3-hole razor blade 0.13mm | 43x22x0.13mm | Ceramic-coated cutting edge | |

Rounded 3-hole razor blade 0.20mm | 43x22x0.20mm | Ceramic-coated cutting edge | |

Long 3-hole razor blade 0.30mm | 60x22x0.30mm | Ceramic-coated cutting edge | |

Rounded slotted razor blade 0.38mm | 57x19x0.38mm | Ceramic-coated cutting edge | |

Slotted razor blade 0.40mm | 57x19x0.40mm | Ceramic-coated cutting edge | |

Rounded slotted razor blade 0.38mm | 57x19x0.38mm | Fully coated with ceramic | |

Injector razor blade | 38x8x0.25mm | Ceramic-coated cutting edge | |

Custom-made machine knives and blades | |||

Circular rotary slitter knife Øe30mm | Ø30x17x0.10mm | Fully coated with ceramic | |

Pointed blade Martor 761 | 33x26x0.90mm | Fully coated with ceramic | |

Machine knife, guillotine type | 90x32x2mm | Fully coated with ceramic | |

Trapezoid knife small 28mm Ø3.6mm | 28x9x0.40mm | Ceramic-coated cutting edge | |

Sollex K- and X-series blades routinely extend service life from days to weeks on the same machine, reduce dust and pickup, and keep slit quality stable through the end of the roll. If your line runs filled, printed, or laminated films and you’re tired of mid-shift blade changes, start with 5K. If buildup on the blade face has been your bottleneck, go straight to 5X.

Feel free to contact us at +4635-15 75-00 if you have any questions regarding our ceramic-coated converting knives and blades.

FAQ

Q: What is the advantage of ceramic coating on razor blades VS uncoated steel?

A: Ceramic coating provides a hard, slick layer that resists adhesive wear, reduces friction, and helps keep edges cleaner for longer, reducing blade changes and improving cut consistency.

Q: What are the differences between edge-coated (K-series) and fully coated (X-series) ceramic blades?

A: K-series coating applies only to the edge, preserving blade geometry and stiffness; X-series covers the whole blade surface, offering better protection against buildup, inks, and abrasive materials for demanding applications.

Q: For which materials or production conditions do ceramic coatings offer the greatest benefit?

A: Materials with heavy fillers (e.g. CaCO₃, TiO₂), printed or laminated films, adhesive-rich webs, and high-speed runs benefit most due to reduced drag, less pickup, fewer stops, and more consistent cut quality.

Q: How much longer do Sollex ceramic-coated blades last under abrasive conditions compared to uncoated blades?

A: Under harsh, abrasive conditions, ceramic coating can extend blade life by 5-8× compared to equivalent uncoated blades, decreasing downtime and maintenance costs.

Q: What should I consider when choosing between different coating types (like Z, V, K, X) for ceramic blades?

A: Choose based on material type, filler content, adhesive or ink presence, line speed, and run length, e.g., Z for thin virgin stretch or speed, K for filled films, X for heavy additives or sticky materials, V for rubbery PP.