Blade for Slitting of EVA & EBA Plastic Films

Plastic ethylene vinyl acetate (EVA) and ethylene butyl acrylate (EBA) are named by plastic film manufacturers as some of the most difficult materials to slit and convert. Their elasticity, chemical structure, and frequent use in multilayer constructions reveal the limitations of traditional steel industrial razor blades. In this article, we discuss what is arguably the only and most effective solution for these applications: an industrial razor blade specifically suited for cutting and converting EVA and EBA plastic films.

EVA Plastic Film in Industrial Slitting

Ethylene Vinyl Acetate (EVA) is known as one of the most degrading plastic films in industrial slitting applications. Its combination of elasticity, durability, and multilayer construction places high mechanical stress on the cutting edge and quickly exposes the limitations of standard steel slitter razor blades.

Ethylene Vinyl Acetate (EVA) is known as one of the most degrading plastic films in industrial slitting applications. Its combination of elasticity, durability, and multilayer construction places high mechanical stress on the cutting edge and quickly exposes the limitations of standard steel slitter razor blades.

EVA plastic film applications

EVA film is chosen for applications where performance under varying environmental conditions is essential. Plastic films with high durability, good light transmission, energy-saving properties, elasticity, and strong temperature adaptability characterize EVA plastic film. Typical applications include greenhouse foil, protection for football pitches and golf greens, frost protection, and shielding of workplaces. EVA film is also available as flame-retardant and is often manufactured in multilayer or laminated structures to combine several functional properties in one material.

One of the most popular and complex applications of EVA film recently is its use in the photovoltaic industry as an encapsulant in solar panels. Thin sheets of EVA are used as sealing layers surrounding the solar cells.

Why EVA film is difficult to slit

From a slitting perspective, EVA’s elasticity means the material resists separation and tends to stretch at the cut point rather than fracture cleanly. The result is accelerated slitter blade degradation, unstable cuts, and frequent blade changes if the blade is not designed for highly degrading films.

Slitting laminated EVA film

Slitting laminated EVA film places particularly high demands on the slitting razor blade. Several layers with different abrasive characteristics pass the blade simultaneously, creating uneven and aggressive wear patterns.

EBA Plastic Film in Industrial Slitting

Ethylene Butyl Acrylate (EBA) is a different polymer than EVA, but from a slitting perspective it presents similarly severe challenges. EBA belongs to the family of ethylene copolymers and is characterized by high softness, flexibility, good polarity, and excellent low-temperature performance. These properties make EBA attractive for demanding film applications, but they also make clean and stable slitting difficult.

EBA plastic film applications

EBA plastic films are used across a wide range of applications, including monolayer and multilayer films, modifier films, heavy-duty films, HF-weldable films, agricultural films, packaging films, peel-and-seal structures, frozen-goods films, gloves, and technical containment films such as urine bags.

Why EBA film is difficult to slit

From a slitting standpoint, EBA behaves as a highly elastic and ductile material. Like EVA, it resists clean separation and tends to deform at the cut interface. However, EBA often exhibits even higher adhesion to the slitter blade edge due to its polarity, increasing friction and thermal load during slitting. In multilayer constructions, EBA is frequently combined with other polymers, causing mixed and uneven abrasive wear on conventional razor blades. As a result, converters often experience unstable slit edges, rapid blade wear, and inconsistent production if blade material is not carefully selected.

Why Steel Slitting Razor Blades Fail on EVA and EBA

Extensive trials carried out by Sollex customers operating industrial plastic film extrusion and converting lines show that most conventional razor blades degrade too quickly when exposed to EVA or EBA films. Edge rounding, chipping, dust formation, and unstable slit quality are common failure modes. This sharply limits viable blade choices.

Extensive trials carried out by Sollex customers operating industrial plastic film extrusion and converting lines show that most conventional razor blades degrade too quickly when exposed to EVA or EBA films. Edge rounding, chipping, dust formation, and unstable slit quality are common failure modes. This sharply limits viable blade choices.

In practice, there are very few blade materials capable of maintaining a stable cutting edge when slitting EVA or EBA film types. Standard carbon or stainless steel blades lose sharpness quickly. Coated steel blades may improve lifetime marginally, but industrial coatings tend to wear unevenly under the combined elastic and abrasive loads of these films. The core issue is not sharpness alone, but how the cutting edge degrades over time.

Sollex blade recommendation for EVA, EBA film

However, Sollex offers a blade that not only delivers excellent results when cutting EVA and EBA films, but also features self-sharpening cutting edges, which solve the above-mentioned problems.

Sollex 5C slotted slitter blade for razor slitting

Sollex 5C slotted slitter blade is manufactured from solid zirconium dioxide (ZrO₂) ceramic and is engineered specifically for highly degrading plastic film materials such as EVA or EBA. 5C differs  fundamentally from steel-based razor blades. Solid ceramic stands out through its high wear resistance, oxidation resistance, non-conductive properties, and temperature resistance up to approximately 600 °C. These characteristics are particularly important when slitting elastic flexible materials that generate frictional heat and adhesive forces at the cutting edge.

fundamentally from steel-based razor blades. Solid ceramic stands out through its high wear resistance, oxidation resistance, non-conductive properties, and temperature resistance up to approximately 600 °C. These characteristics are particularly important when slitting elastic flexible materials that generate frictional heat and adhesive forces at the cutting edge.

Compared with conventional industrial blades, the 5C maintains a more controlled wear pattern, supporting cleaner slit edges and more predictable production runs.

Sollex 5C solid ceramic razor blade is particularly suitable for cutting several layers of laminated film, where different highly abrasive materials lie on top of each other and wear down the razor blade in different ways. In laminated and multilayer EVA or EBA films, the 5C blade maintains a controlled wear pattern. Importantly, customer trials across industrial film extrusion and converting operations consistently tell that alternative blade materials fail.

The main feature of the 5c blade is that when this Sollex ceramic slitter blade is used to cut abrasive materials, it sharpens itself and becomes even sharper, rather than becoming dull like other razor blades. This results in cleaner slit edges, longer blade life, and more predictable production runs.

Based on multiple industrial trials performed by leading plastic film extrusion and converting companies, the Sollex 5C has proven to be the most reliable blade for both EVA and EBA plastic film slitting. In many cases, converters report that alternative blade materials fail to deliver acceptable stability, making the 5C not just a recommendation but effectively the only blade option that performs consistently for these applications.

Some limitations of ceramic slitter razor blades

There are some solid ceramic blades disadvantages, namely their relatively high price and the fragility of the ceramic material. However, although ceramic blades for industrial cutting, including 5C, are more expensive due to the material from which they are made and the complexity of sharpening their cutting edges and manufacturing them, ceramic blades are the most cost-effective and durable in the long term when cutting the particular flexible material.

In addition, the fragility of ceramic materials limits the types of materials that can be cut with them. Flexible materials such as PCR or PIR plastic films are not recommended for cutting with ceramic blades due to the presence of hard particles or additives.

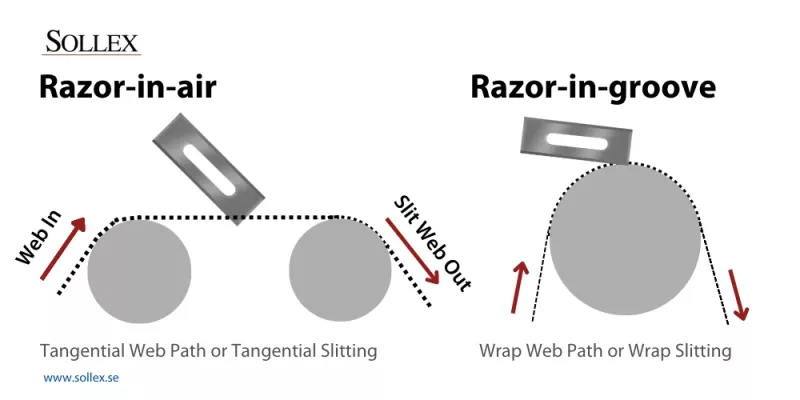

Ceramic blades are best used for cutting in the air rather than in a groove to avoid the risk of vibration and collision with a hard object, which could break the blade.

In addition, careful storage and transportation are essential.

Razor blades for plastic film slitting and converting

Razor slitting is the simplest and most cost-effective way to cut thin films, foils, and laminates. With the right blade material, coating, and holder setup, converters can achieve clean, narrow edges at high speeds with minimal downtime. Sollex supplies a wide range of industrial razor blades, from standard carbon steel to solid tungsten carbide and advanced coatings, ensuring reliable performance in every application.

Sollex has high quality industrial razor blades for any kind of application. Our industrial-type razor blades are made of high-chromed carbon steel, stainless steel, solid tungsten carbide, and zirconia ceramic, and additional coatings of the blades are our strength.

If you do not find the razor blade you are looking for, Sollex are able to manufacture industrial razor blades according to your drawing.

Download PDF with Sollex Blades for Plastic Industry

Feel free to contact us at +4635-15 75-00 if you have any questions regarding our industrial razor blades.