Blades for Cast Film Extrusion & Web Trimming

This article focuses on the cutting processes used in cast plastic film production and explains which blades our customers consider the most reliable for web edge trimming on modern cast film extrusion lines. You will also find a short case study from one of the largest global manufacturers of cast and blown film, where Sollex industrial razor blades improved cutting stability significantly.

For readers who want to explore the blown film process, slitting methods, and blade recommendations for other types of extrusion, we recommend the Sollex article “Blades for Blown Film Extrusion, Flexographic Printing, and Converting.”

Content:

- Overview of the cast film production process

- Basic types of cast film and their applications

- Major manufacturers of cast film manufacturing lines

- Cutting processes in cast film production

- Blades for cast film extrusion and web trimming

- Customer case

Overview of the Cast Film Production Process

Cast film extrusion is used to produce clear, smooth, and highly uniform plastic film at high speed. The process is widely applied for cast PP, PE, PET, stretch LLDPE, barrier films, MDO films, and multilayer structures that range from simple monolayer webs to advanced seven-layer co-extrusions. Thickness typically lies between 10 and 50 microns, and cast lines are chosen when consistent optical quality and high output are required.

Cast film extrusion is used to produce clear, smooth, and highly uniform plastic film at high speed. The process is widely applied for cast PP, PE, PET, stretch LLDPE, barrier films, MDO films, and multilayer structures that range from simple monolayer webs to advanced seven-layer co-extrusions. Thickness typically lies between 10 and 50 microns, and cast lines are chosen when consistent optical quality and high output are required.

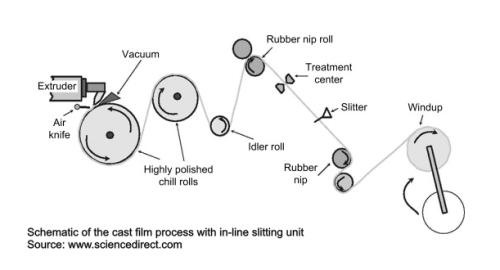

The process begins when polymer granules are blended, melted in the extruders, and pushed through a wide flat die such as a T-die or coat hanger die. The melt exits as a thin curtain and lands on a polished, water-cooled chill roll that rapidly freezes the film. In multilayer production, a feedblock combines several molten layers before they enter the die, and infrared sensors help maintain uniform temperatures and thickness across the full width.

Once cooled, the web passes through a roll stack where final properties are developed before reaching the edge trimming and surface-treatment section. Once trimming is complete, surface treatment such as corona can be applied when printing, coating or metallizing is needed. The finished web is then wound into rolls.

Cast film extrusion is known for its efficiency. Commonly cast film extrusion lines run at 200-500m/min with an output of up to 1000kg per hour, making the process cost-effective in continuous production despite higher equipment investment. The result is excellent thickness control, high clarity, and a smooth surface suitable for printing. The main limitations are the initial equipment cost, less balanced mechanical strength compared with blown film, and more restricted maximum widths.

Advantages and Disadvantages of Cast Film Extrusion

Advantages | Disadvantages |

|---|---|

Very high production speeds and high output per hour | Higher initial equipment cost |

Excellent thickness control and uniformity | Less balanced mechanical properties compared with blown film |

Superior optical clarity and smooth surface finish | More limited maximum width range |

Stable film shape and reduced web breaks | Not ideal when detailed property control is required |

Efficient for large volume production | |

Suitable for high-quality printing and coating |

Basic Types of Cast Film and Their Applications

Cast plastic film ranges from simple monolayer structures to advanced 7-layer co-extrusions. Modern cast film systems can process PP, PE, PET, stretch LLDPE, barrier materials, and MDO films, which makes the technology suitable for both high-volume packaging and highly technical applications.

Monolayer cast films are used for standard packaging, surface protection, and general industrial applications. They offer good clarity and stable thickness at high production speeds.

Co-extruded cast films are more common and allow several functional layers in one structure. These include hygiene films, CPP film, CPE film, stretch and cling film, masking film, agricultural and greenhouse film, medical films, and barrier films for food packaging.

Cast polypropylene film CPP and cast polyethylene film CPE are the most widely produced cast films. CPP film provides excellent transparency, printability, metallization quality, and heat seal performance, which makes it ideal for food packaging and lamination. CPE film offers very good clarity and consistent thickness, often used for laminates and surface protection films.

Barrier cast films are produced when oxygen or moisture protection is required. They are used in food packaging, medical packaging, and pharmaceutical pouches. Cast PET films serve similar markets and are valued for strength, clarity, and dimensional stability.

Mono-oriented cast films such as MOPP and MOPE expand the range of technical uses. Their tensile strength and stiffness make them suitable for stand-up pouches, label films, carrier handles, tear tapes, foamed labels, adhesive tapes, decoration tapes, and cable insulation. Hygiene backsheet film and roofing film also fall within this group.

Beyond packaging, cast film lines are used for demanding technical products in electronics, lithium-ion batteries, optical surface protection, and pharmaceutical applications where uniformity, transparency and surface quality are critical.

Major Manufacturers of Cast Film Manufacturing Lines

There are many suppliers of cast film extrusion technology worldwide. In daily work with plastic film manufacturers and extruders, Sollex often encounters extrusion lines from several key manufacturers. These systems dominate the market segments where our customers operate, especially in stretch film, CPP and CPE film, barrier film, and technical co-extruded products.

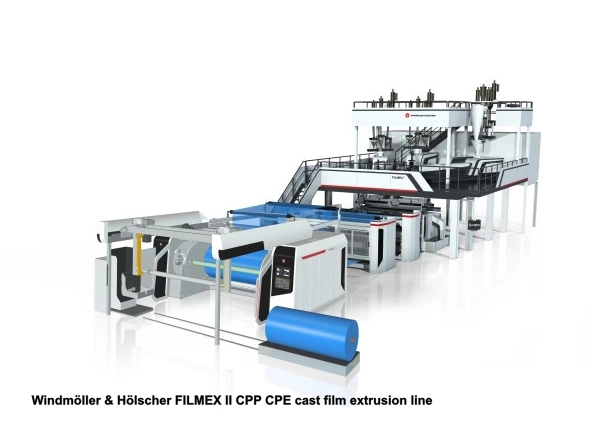

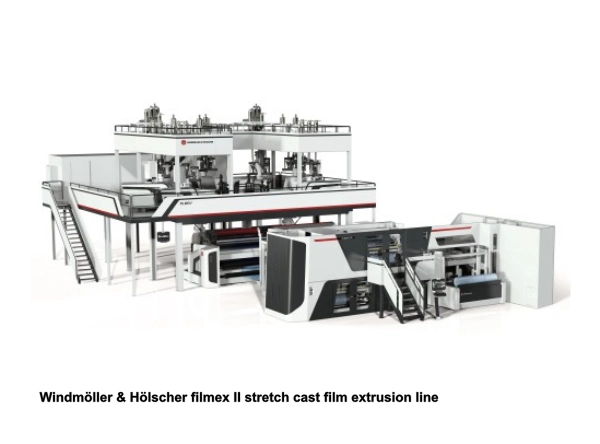

Windmöller & Hölscher

Windmöller & Hölscher is a leading supplier of both blown and cast film extrusion systems. The Filmex II platform is available in several configurations, including Filmex II Stretch for stretch LLDPE, Filmex II CPP and CPE for polyolefin packaging films, and Filmex II Barrier for multilayer structures that require advanced gas or moisture protection. These lines are known for stable production, high output, and precise thickness control.

SML

SML offers one of the broadest portfolios in the cast film market. Their range includes compact MiniCast and EcoCompact lines for smaller operations, SmartCast and PowerCast for high-speed production, and MasterCast lines for wide and complex co-ex films. SML systems are used for stretch film, CPP and CPE film, cast PET, barrier films, MDO mono-oriented films, lithium-ion battery separator films, and hygiene applications. Among Sollex customers, SML lines are especially common beyond the bigger plastic manufacturers because of their strong process stability.

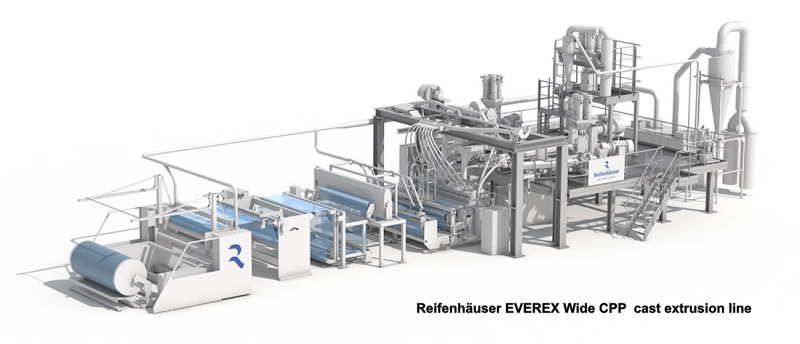

Reifenhäuser

Reifenhäuser produces the Everex series, which includes wide CPP lines, barrier cast film systems, and dedicated solutions for hygiene and industrial films. Their technology is widely used for demanding co-ex structures in packaging and technical applications. CPP and PE cast film lines from the Everex family are common among manufacturers who prioritise excellent optical quality and robust multilayer control.

Colines

Colines is a well-known supplier of cast film technology, especially for stretch film and multilayer barrier structures. Their ALLrollEX stretch film lines are widely used for high-speed production with consistent gauge control, while the POD barrier film lines support complex multilayer and nanolayer structures for food and technical packaging.

AMUT

AMUT supplies cast film lines primarily focused on stretch film production. Their systems are designed for consistent thickness, high transparency, and stable winding quality. AMUT lines are frequently found in facilities that run large volumes of stretch LLDPE where predictable output and durable slitting solutions are essential.

Cutting Processes in Cast Film Production

Cutting is an essential part of cast film production and takes place both on the extrusion line and later in the converting stage. Three types of cutting are used: mandatory web edge trimming during cast film extrusion, occasional in-line roll slitting, and post-production converting on dedicated slitter machines. As a result, both film manufacturers and converters require reliable blades for different stages of the process.

Web Edge Trimming

Edge trimming is a constant step in cast film extrusion. After the melt is cooled on the chill roll, the web develops slight edge thickening called the edge bead. These unstable margins are removed before surface treatment to avoid backside corona and to achieve a clean and accurate roll width.

Edge trimming systems consist of the cutting unit and the trim handling system. Trim strips are captured by blowers or vacuum conveyors and transported to a grinder or agglomerator. The material is chipped, melted, or pelletised depending on the recycling setup.

Razor slitting is the dominant method for edge trimming. Cast lines typically run at several hundred meters per minute, which requires sharp, low-friction razor blades to produce a clean fracture edge. Standard razor blades work well up to about 300 meters per minute. At higher speeds, coated industrial razor blades are used to maintain edge quality and extend blade life despite the extreme web velocity.

In-line Roll Slitting

In-line slitting is technically possible but less common in cast film production. The web moves at very high speed, which complicates process control and increases the risk of dust, melted edges, or winding defects. For this reason, cast film lines primarily use edge trimming and wind the web at full width. In-line slitting is more typical in blown film production where line speeds are lower and the process is easier to stabilise.

Converting in Slitter Rewinders

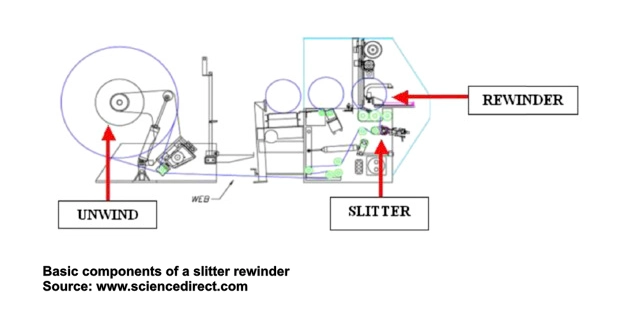

After extrusion, the finished rolls are moved to converting equipment where they are slit to final customer widths. Slitter rewinders use razor, shear, or score cutting depending on the material and application.

Razor cutting remains the most widely used method for cast PP, CPE, PE, PET, and barrier films thanks to its simplicity and clean slit quality. Blades are placed in holders and positioned across the web to create multiple narrow rolls. Converters also use shear slitting, where two rotating circular knives work like scissors for thicker or stiffer materials, and score slitting, where a blade runs in a groove of an idler roll to score the film surface.

Blades for Cast Film Extrusion and Web Trimming

Edge trimming on cast film lines takes place under extreme conditions. Modern lines routinely run above several hundred meters per minute and produce tonnes of film per hour. Under these conditions, the industrial razor blade for web trimming becomes a critical process component. The wrong blade can cause dust, unstable trim, and unplanned stops. On the other hand, the right blade can run for weeks without intervention and keep the winder perfectly stable.

Now we will look at a real customer case where a slitting razor blade developed specifically for high-speed cutting lines. It is a good example of how blade geometry, coating, and size directly influence output and long-term operational cost.

Customer Case

A global manufacturer of stretch film operates several cast lines that produce thin plastic film at extremely high throughput. Their process parameters are demanding:

A global manufacturer of stretch film operates several cast lines that produce thin plastic film at extremely high throughput. Their process parameters are demanding:

- Web speed routinely above 400 meters per minute

- Hourly output close to 2000 kilograms

- Film thickness in the very low micrometer range

Under these conditions, standard slitting razor blades reached their limits. Operators reported fluctuating trim quality, increased dust formation, and frequent blade changes.

Sollex introduced a blade adapted for these load conditions: 4-60-030-Z. The blade has a 60 millimeter length instead of the standard 43 millimeters, a thickness of 0.30 millimeters, and Sollex Zero Friction coating on the cutting edges. The blade should be set at a 45 degree cutting angle, which helps maintain a stable web slit even at maximum speed.

During validation the customer ran the blade at 468 meters per minute on a continuous shift. Trim quality remained stable, and operators reported no dust issues. The most striking result came from blade life. Where the previous solution lasted only several days, the 4-60-030-Z remained in operation for 6 weeks without replacement. For a plant producing thousands of tonnes per month, this improvement meant fewer stops, more predictable winding, and a notable reduction in maintenance time.

Recommended Blade Setup for Cast Film Edge Trimming

Experience from multiple cast film producers shows that certain parameters consistently lead to better performance on high-speed lines:

- Longer razor blades. The 60 millimeter long razor blade provides greater stability in the holder and improves cut accuracy across the full trim width.

- Thicker razor blades. A thickness of 0.30 millimeters reduces vibrations and keeps the slit clean during continuous high-speed production.

- Coated razor blades. Low-friction coatings such as Sollex Zero Friction reduce heat development, prevent material buildup on the blade, and increase lifetime significantly.

- The right blade and holder settings. A 45 degree cut angle provides the most consistent web break and minimizes the risk of melt smearing or dust.

These elements together form a reliable configuration for any cast film line running at several hundred meters per minute, especially those producing thin stretch film where edge quality directly influences winding performance.

Sollex Blades Deliver High-Quality Slitting Results

Sollex, as a supplier for over 98 years and a leader in industrial-type razor blades, circular knives, shear cut knives, crush cut knives, pointed blades and custom-made solutions for the plastic industry, will provide you with slitting blades that guarantee the best cut and result for your specific application.

Download PDF with Sollex Blades for Plastic Industry

Feel free to contact us at +4635-15 75-00 or order@sollex.se if you have any questions regarding our industrial razor blades or slitting industrial knives.

FAQ

Q: What are the key advantages of the cast film extrusion process?

A: Cast film extrusion offers very high production speeds, excellent thickness control, superior optical clarity, a smooth surface finish, and is efficient for large-volume production of films like LLDPE, CPP, and CPE.

Q: What is web edge trimming, and why is it mandatory during cast film extrusion?

A: Web edge trimming is the process of removing the slight, unstable edge thickening (edge bead) that forms after cooling. This is mandatory to achieve a clean, accurate roll width and prevent backside corona treatment before winding.

Q: What is the dominant cutting method used for web edge trimming on high-speed cast lines?

A: Razor slitting is the dominant method for web edge trimming. It requires sharp, low-friction razor blades to produce a clean fracture edge, especially since lines run at several hundred meters per minute.

Q: What three blade features are recommended for high-speed cast film edge trimming (above 300m/min)?

A: It is recommended to use Longer razor blades (60mm for stability), Thicker razor blades (0.30mm for reduced vibration), and Coated razor blades (like Sollex Zero Friction) to reduce heat and material buildup.

Q: Which cutting angle is recommended for maintaining a stable web slit during edge trimming?

A: A 45 degree cut angle is recommended as it provides the most consistent web break and minimizes the risk of melt smearing or dust, especially when running at maximum speed.

Q: What specific results did the Sollex 4-60-030-Z blade achieve in the customer case study?

A: The blade ran at 468 meters per minuts and lasted 6 weeks without replacement, significantly improving trim quality, eliminating dust issues, and extending blade life compared to the previous solution.

Q: Why is in-line roll slitting less common in cast film production compared to blown film?

A: In-line slitting is less common because the cast film web moves at very high speed, which complicates process control and increases the risk of dust, melted edges, or winding defects.

Q: What types of advanced film structures are produced on modern cast film lines?

A: Modern cast lines produce materials like cast PP, PE, PET, stretch LLDPE, barrier films (for oxygen/moisture protection), and MDO mono-oriented films (for stand-up pouches and label films).