Slitter Razor Blades: Overview [Video]

Industrial blades and knives for the plastics industry

In this article, we explain what slotted slitter blades are, how they are used in industrial razor slitting, and why they are essential for film, foil, and plastic converting. You will learn the key features of slotted slitter blades, the different blade materials such as carbon steel, stainless steel, ceramic, and tungsten carbide, and how coatings improve performance. We also cover the main application areas, typical slitter rewinder machines, and expert tips to achieve the best cutting results with Sollex industrial blades.

Content:

- About slotted slitter razor blades

- Features, dimensions

- Blade materials

- Applications, machines

- Sollex slitter razor blade overview

- Expert cutting tips

- Order industrial razor blades from Sollex

- FAQ

Slotted Slitter Blades for Industrial Razor Slitting of Flexible Materials

Slotted slitter blades, along with 3-hole blades, injector blades, and Gillette-type blades, are blades used in industrial razor slitting processes. They are employed in slitter rewinder machines to convert and cut flexible materials into narrow strips that are then rewound into neat rolls. These blades are essential in producing precise, high-quality cuts and are widely used across various industries.

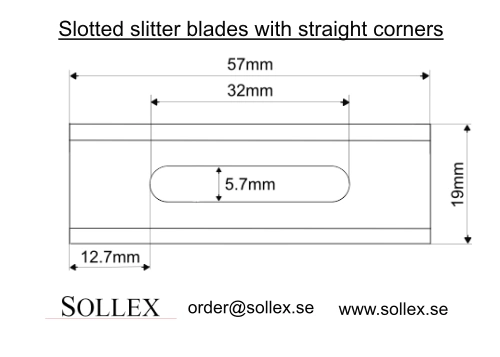

Industrial slotted slitter blades have a rectangular shape, typically measuring 57x19 mm. Unlike 3-hole slitter blades, the slotted variant has a robust design with a single oblong slot in the center. This design allows for the cutting of not only basic plastic films such as polyethylene (PE) and polypropylene (PP) but also thicker, more abrasive materials with additives or impurities, including recycled films and those with calcium carbonate fillers.

Slotted slitter blades are available in thicknesses of 0.20 mm, 0.38 mm, and 0.40 mm, and can feature straight or rounded corners to match the material and application. The blade’s thickness and design play a significant role in cutting performance, especially when dealing with challenging materials in foil slitting and plastic slitting processes.

Industrial Razor Blade Materials Overview

Slotted slitter blades are manufactured using a range of high-quality materials, each chosen to ensure durability, precision, and optimal cutting performance:

Blade Material | Key Properties | Advantages |

Carbon steel | High hardness and affordability | Ideal to convert simple plastic films with minimal additives |

Stainless steel | Corrosion resistance and long-lasting sharpness | Suitable for clean environments and basic plastic films |

Ceramic | Exceptional wear resistance and low friction | Well-suited for films with additives and demanding cutting conditions |

Solid tungsten carbide | Extreme hardness and resistance to wear and deformation | Effective for hard laminated films and composite materials slitting |

Zero friction (coated) | Reduced friction, minimal heat generation | Perfect for thin, stretch films processing |

Titanium | High corrosion resistance | Ideal for specialized applications requiring robust blades |

Razor Blade Application Areas & Typical Slitter & Converting Machines

Slotted slitter blades are used in a wide array of slitting and converting machines, ensuring precise cuts and minimal waste. Common applications and machines include:

Application Area | Typical Machines and Equipment |

Flexible packaging | Slitter rewinder machines, including those by Kampf, Atlas, and Goebel |

Label production | Label slitting and finishing equipment |

Paper and film converting | Narrow web slitter rewinders, turret rewinders |

Laminated films and barrier packaging | Duplex and duplex-turret slitter rewinders |

Recycled plastic films | High-speed slitter rewinders with tension control |

The slotted slitter razor blades excel in cutting a broad range of materials, thanks to their robust construction and precise edge geometries.

Material Cut | Examples and Applications |

Simple plastic films | PE (polyethylene), PP (polypropylene) |

Films with additives | White plastic films, composite films |

Recycled films | Plastic films containing calcium carbonate or other fillers |

Laminated and multi-layered films | Flexible packaging films, barrier films |

Soft flexible foils | EBA (ethylene butyl acrylate) and similar foils |

Thin stretched films | Stretch and shrink films for packaging |

Rubber and foils | Lightweight technical materials in packaging and insulation industries |

Sollex Slotted Razor Blades – Product Overview

Our Sollex industrial-type slitting blades are tailored to meet the exacting needs of modern converting processes:

SKU | Blade Material | Application | Thickness (mm) | Pack (pcs) |

Carbon steel | Simple plastic films | 0.20 | 200 | |

Ceramic | White films with additives | 0.40 | 100 | |

Stainless steel | Simple plastic films | 0.40 | 100 | |

Tungsten carbide | Laminated films and plastic packaging | 0.38 | 10 | |

Ceramic | Soft flexible film foils (EBA) | 0.40 | 10 | |

Zero friction coated | Thin stretched films | 0.20 | 200 | |

Ceramic | White films with additives | 0.38 | 100 | |

Zero friction coated | Thin stretched films | 0.38 | 100 | |

Titanium | Plastic films with additives | 0.38 | 100 | |

Solid ceramic | Multilayer plastic films | 0.38 | 30 |

Sollex Slotted Razor Slitting Blades include various models for different applications. The 5-020 carbon steel blade is intended for simple plastic films with few additives and is 0.20 millimeters thick, packed in sets of 200. The 5Q ceramic blade is suitable for white plastic films with additives, measuring 0.40 millimeters in thickness and available in packs of 100. The 5L stainless steel blade is also 0.40 millimeters thick and designed for simple plastic films with minimal additives. The 5V solid tungsten carbide blade is ideal for hard laminated films and plastic packaging, with a thickness of 0.38 millimeters and packed in sets of 10. The 5C solid ceramic blade, measuring 0.40 millimeters thick, is best suited for soft flexible film folies. The 5-020-Z zero friction blade is perfect for thin stretched film at 0.20 millimeters thick and comes in sets of 200. The 5K ceramic blade, with a thickness of 0.38 millimeters, is used for white plastic films with additives. The 5Z and 5LZ zero friction blades are also 0.38 millimeters thick and designed for thin stretch films. The 5T titanium blade is 0.38 millimeters thick, developed for plastic films with additives. The 5X solid ceramic blade, measuring 0.38 millimeters, is ideal for multilayer plastic films with additives. Each blade is precision-crafted to deliver consistent, high-quality results in slitting and rewinding applications.

Sollex Slotted Razor Slitting Blades include various models for different applications. The 5-020 carbon steel blade is intended for simple plastic films with few additives and is 0.20 millimeters thick, packed in sets of 200. The 5Q ceramic blade is suitable for white plastic films with additives, measuring 0.40 millimeters in thickness and available in packs of 100. The 5L stainless steel blade is also 0.40 millimeters thick and designed for simple plastic films with minimal additives. The 5V solid tungsten carbide blade is ideal for hard laminated films and plastic packaging, with a thickness of 0.38 millimeters and packed in sets of 10. The 5C solid ceramic blade, measuring 0.40 millimeters thick, is best suited for soft flexible film folies. The 5-020-Z zero friction blade is perfect for thin stretched film at 0.20 millimeters thick and comes in sets of 200. The 5K ceramic blade, with a thickness of 0.38 millimeters, is used for white plastic films with additives. The 5Z and 5LZ zero friction blades are also 0.38 millimeters thick and designed for thin stretch films. The 5T titanium blade is 0.38 millimeters thick, developed for plastic films with additives. The 5X solid ceramic blade, measuring 0.38 millimeters, is ideal for multilayer plastic films with additives. Each blade is precision-crafted to deliver consistent, high-quality results in slitting and rewinding applications.

Expert Tips from Sollex: How to Achieve Optimal Cutting Results

The choice of knife configuration, such as shear, razor, crush cut, or score cut, depends on the material being processed and the desired slit quality. Factors such as blade sharpness, angle, and positioning influence the cutting performance and the quality of the finished rolls. Precise adjustment of blade gap, overlap, ensure optimal cutting performance and minimizes material waste. While specific values for factors such as knife positioning, tension control, and slitting speed can vary  depending on the material being processed, the equipment used, and other factors, we can provide some general guidelines and recommended values.

depending on the material being processed, the equipment used, and other factors, we can provide some general guidelines and recommended values.

- The cutting angle is crucial: 45 degrees for razor slitting and 90 degrees for shear cutting.

- Blades must always be sharp to maintain top cutting performance; keep a stock of replacement blades for continuous production.

- Match the blade thickness to the material’s thickness, accounting for additives and slitting speed.

- High cutting speeds can generate excessive heat at the blade edge, causing film melting and poor-quality cuts.

- Blade coatings reduce edge heating caused by friction, preserving cut quality.

- Material elasticity influences tension control; more elastic materials demand precise tension adjustments to prevent stretching or wrinkling.

- Tension variation should be kept within five percent of the target to ensure consistent slit and rewound rolls.

- In shear slitting, four factors are critical: blade overlap (0.50–0.75 mm), cut point, side loading pressure, and cant angle (0.25 degrees for films). Adjust slitter and web speeds, and blade profiles for the best result.

- Always conduct tests and consult equipment manufacturers and industry experts to optimize settings for each specific application.

While these tips and guidelines offer a solid foundation, adapting them to your unique production environment is key. Continuous testing and collaboration with experts can uncover additional ways to enhance cutting quality and production efficiency. With the right approach and attention to detail, achieving top-tier slitting and rewinding results is well within reach.

Order Film & Foil Slitting Razor Blades for Industrial Cutting

At Sollex, we offer not only the best razor blades for slitting but also the technical knowledge and support to help you choose the most suitable blade material and configuration for your specific needs. Explore our range of slitter blades, including slotted slitter blades, foil slitting blades, plastic slitting blades, and industrial slitting blades, and elevate your slitting operations to the highest standards.

FAQ

Q: What are slitter blades used for?

A: Slitter blades are industrial cutting tools used to slit wide rolls of materials such as plastic film, paper, foil, or nonwoven into narrower rolls with high precision and clean edges.

Q: What types of slitter blades are available?

A: Common types include industrial razor blades (three-hole, slotted, or injector formats) for thin films, and circular slitting knives for higher-throughput lines or tougher materials.

Q: Which materials can be cut with slitter blades?

A: Slitter blades from Sollex are used for plastic films (BOPP, PET, PE, PLA, etc.), paper, laminates, foil, and nonwoven fabrics. The blade format and edge design are chosen depending on the material’s thickness and properties.

Q: Why are coatings important for slitter blades?

A: Coatings such as titanium nitride (TiN), ceramic, or low-friction layers increase wear resistance, reduce buildup, and extend blade life, lowering production downtime and scrap rates.

Q: How long do slitter blades typically last?

A: Lifespan depends on the material being cut and the blade’s coating. A coated blade may last several times longer than an uncoated one, especially in abrasive or high-speed production.

Q: Can slitter blades be resharpened?

A: Disposable razor blades are replaced when worn, while circular knives can be professionally reground as long as hardness and geometry remain within specification.

![Sollex Slitterblad [Video] Industrirakblad och knivar för plastfilmindustri](https://cdn.starwebserver.se/shops/sollex-se/files/cache/sollex-slitter-blades-blog_large.jpg?_=1634281635)