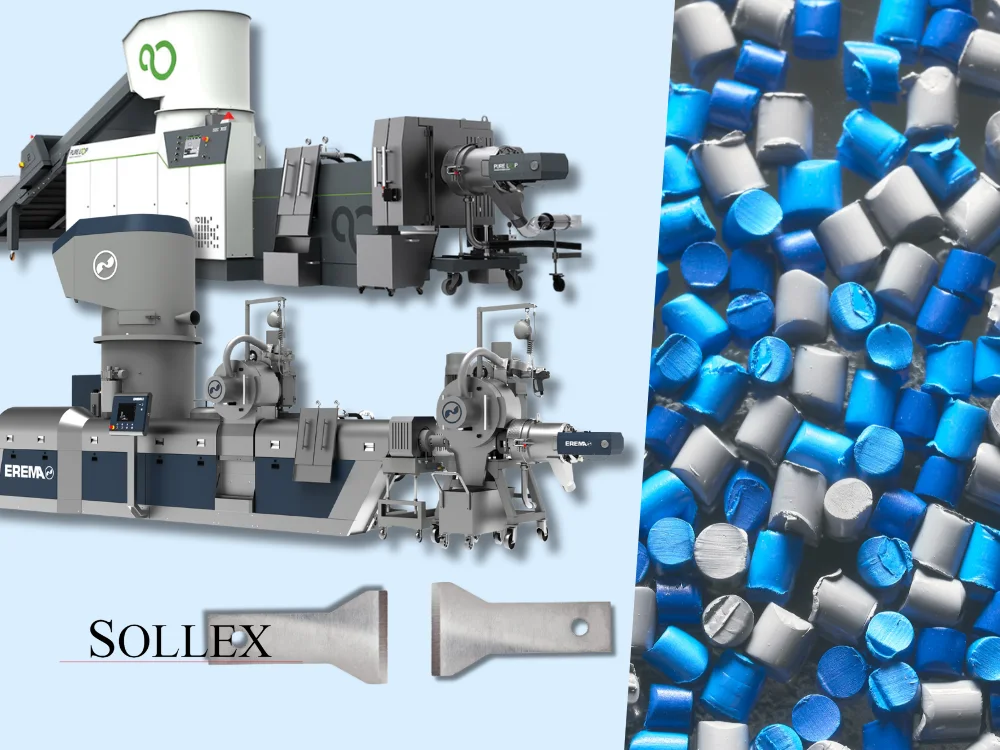

Pelletizer knives for PURE LOOP and EREMA recycling systems

Recycling production waste in modern plastic manufacturing

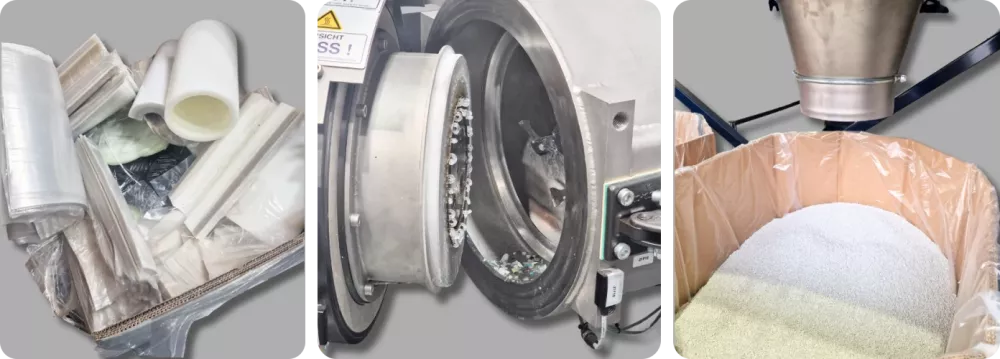

Every plastic film converting or extrusion plant generates a certain amount of clean production plastic waste. By-products of normal operation include edge trim, off-spec rolls, and start-up film material. Instead of treating these materials as waste, many producers now invest in in-house recycling systems that turn clean scrap into new pellets for reuse. This approach helps companies achieve sustainability goals by reducing material costs, reducing transport and waste fees, and maintaining a closed loop of production resources.

How in-house recycling works

In-house recycling means that production waste is collected and processed directly at the manufacturing site. The scrap is shredded, melted, filtered and pelletized into new plastic granulate that can be fed back into the production line. Because the material never leaves the facility, its composition and cleanliness remain controlled, which allows the recycler to produce high-quality pellets suitable for new film or sheet production. This system significantly lowers the demand for virgin polymer and ensures a predictable raw-material flow.

PURE LOOP and EREMA: trusted names in recycling machinery

PURE LOOP, part of the EREMA Group in Austria, designs equipment dedicated to the recycling of clean industrial waste. Their technology is based on a shredder-extruder combination that processes film trim, edge waste, fibres, and other production residues into uniform recycled pellets. EREMA’s well-known INTAREMA series uses a similar concept for efficient melting, filtration and pelletizing of thermoplastics. Film producers and converters widely use these recycling lines to reuse their own production scrap without compromising quality.

Pure-LOOP systems, such as the ISEC evo series, are designed for continuous operation and stable throughput. The process treats the material gently to preserve polymer properties and ensure that the recycled pellets meet the specifications required for direct reuse. With flexible feeding options, the system can process light films, dense flakes, and edge trim equally well, making it an ideal solution for in-house recycling loops in film converting and extrusion plants.

The pelletizing stage and why knife quality matters

At the end of the recycling process, the molten polymer is cut into pellets. This step determines the appearance and consistency of the recycled granulate. Sharp and stable pelletizer knives ensure that every pellet is cut cleanly and evenly, reducing dust formation and energy consumption. When knives wear out or lose sharpness, the pellet size becomes irregular, which affects downstream processing and may lead to unnecessary machine downtime.

At the end of the recycling process, the molten polymer is cut into pellets. This step determines the appearance and consistency of the recycled granulate. Sharp and stable pelletizer knives ensure that every pellet is cut cleanly and evenly, reducing dust formation and energy consumption. When knives wear out or lose sharpness, the pellet size becomes irregular, which affects downstream processing and may lead to unnecessary machine downtime.

For this reason, choosing the right pelletizer knife is as important as selecting the recycling machine itself. Precision and material quality make a direct difference in how long the knives last, how often the system must be serviced, and how consistent the pellets remain during production.

Sollex L24 pelletizer knives for PURE LOOP and EREMA systems

Sollex pelletizer knives L24 are developed for pelletizing systems used in EREMA INTAREMA, and PURE LOOP recycling lines. These knives are made of premium tool steel with a hard, wear-resistant edge that keeps its sharpness over time. Each knife is produced with precise tolerances to fit the cutting heads of EREMA-type pelletizers and to deliver a smooth and stable cutting action.

Sollex pelletizer knives L24 are developed for pelletizing systems used in EREMA INTAREMA, and PURE LOOP recycling lines. These knives are made of premium tool steel with a hard, wear-resistant edge that keeps its sharpness over time. Each knife is produced with precise tolerances to fit the cutting heads of EREMA-type pelletizers and to deliver a smooth and stable cutting action.

By using Sollex L24 knives, recyclers achieve uniform pellet size, reduced fines, and a lower risk of process interruptions. The clean cut also minimizes mechanical stress on the die plate and improves pellet cooling and downstream handling. For operators running a continuous in-house recycling process, this means longer maintenance intervals and reliable production efficiency.

Advantages for film producers and converters

Film converters and extrusion companies that generate significant edge trim can benefit greatly from integrating in-house recycling systems with high-performance pelletizer knives. The combination of advanced recycling equipment such as PURE LOOP ISEC evo or EREMA INTAREMA with precision knives from Sollex creates a dependable production loop where clean scrap is immediately turned into reusable pellets. This not only reduces production waste but also supports material traceability and resource efficiency.

In-house recycling has become an essential part of sustainable plastic film production. Systems from PURE LOOP and EREMA make it possible to convert clean industrial waste into new, high-quality pellets ready for reuse. To achieve the best pellet quality and stable operation, the pelletizing knives must be as precise as the machinery itself. Sollex pelletizer knives L24 are engineered for compatibility with these recycling systems and deliver excellent cutting performance, long lifetime and consistent pellet results.

For film manufacturers and recyclers who aim to optimize their internal recycling process, the right choice of pelletizer knife is a small detail that brings major results in quality, efficiency and sustainability.

FAQ

Q: What is in-house recycling in plastic production?

A: In-house recycling means processing clean production waste such as film trim, edge scrap, or start-up material directly in the factory to produce reusable plastic pellets.

Q: What does PURE LOOP manufacture?

A: PURE LOOP builds recycling machines that combine a shredder and extruder to convert clean production waste into new plastic pellets for reuse.

Q: How is PURE LOOP connected to EREMA?

A: PURE LOOP is part of the EREMA Group and focuses on recycling clean industrial waste, while EREMA also produces systems for a broader range of plastic recycling applications.

Q: What happens during pelletizing in recycling lines?

A: During pelletizing, the melted plastic is cut into small, uniform pellets which are then cooled and ready to be reused in extrusion or converting.

Q: Why are pelletizer knives important in recycling machines?

A: Pelletizer knives perform the final cut of the molten polymer. Their precision affects pellet size, dust generation, energy efficiency, and machine wear.

Q: Which knives are compatible with PURE LOOP and EREMA systems?

A: Sollex pelletizer knives L24 are made to fit PURE LOOP, EREMA, and INTAREMA pelletizing systems for reliable and precise cutting performance.

Q: What are the main benefits of Sollex L24 pelletizer knives?

A: Sollex L24 knives provide clean and even pellet cuts, long tool life, less dust, and lower maintenance costs during continuous operation.

Q: How can in-house recycling benefit film producers?

A: In-house recycling with systems from PURE LOOP and knives from Sollex allows film producers to reuse their own production waste, cut raw material costs, and improve sustainability.

About Sollex

Sollex is a Swedish supplier of machine knives and industrial slitter razor blades for professional cutting applications. Since 1927 the company has provided high-performance cutting solutions to film producers, plastic converters, recyclers, and packaging manufacturers worldwide.

Download PDF with Sollex Blades for Plastic Industry

The Sollex assortment includes industrial razor blades, slitter blades, pelletizer knives, and granulator knives designed for reliable performance in demanding production environments. Every Sollex product is developed with a focus on sharpness, durability, and precision to ensure clean cuts, longer tool life, and efficient processing.

With close experience in the plastics, recycling, and conversion industries, Sollex supports customers in choosing the right cutting tools for film extrusion, slitting, pelletizing, and compounding. Whether it is a standard knife or a custom-made blade, Sollex offers consistent quality and technical expertise that help optimize productivity and reduce downtime.

For more information about industrial blades and knives for plastic recycling and film converting, contact order@sollex.se or +4635157500.