High Quality Blades for Plastic Film Slitting

Plastic Film Slitting & Converting

Slitting is one of the most important material converting processes and refers to the slitting of a larger roll of plastic film wound on a reel into narrower strips. The process of slitting plastic film is most often performed in conjunction with unwinding processes, as it requires first unwinding the parent roll, slitting the plastic film material with industrial razor blades or slitting machine knives, and then rewinding it onto smaller spools. These processes are performed in parallel on slitter-rewinders - special cutting machines designed to convert plastic film. The slitting and winding of plastic film are the final converting steps in the industrial film production process.

Industrial Razor Blades for Cutting Film

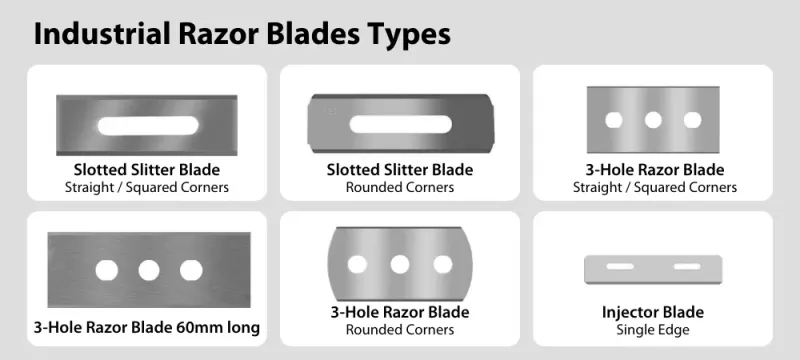

When it comes to razor slitting, Sollex offers the following industrial razor blades for film cutting and converting:

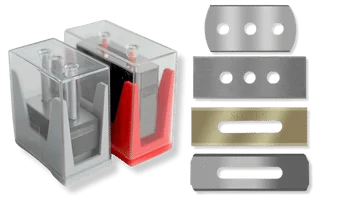

Slotted Slitter Blades. They come with straight or rounded corners. The thickness of these slitter razor blades is 0.40 mm and 0.20 mm. The standard blade size is 57x19x0.40 mm.

Industrial razor blades with 3 holes. These blades also come in straight and rounded corners. The dimensions are 43x22 mm and the thickness of the blades varies from 0.10 mm to 0.40 mm depending on the cutting film material.

Injector blades. These are small industrial blades, usually measuring 38x8x0.25 mm. They have 2 holes for installation in the slitter machine.

The razor cutting method provides the cleanest cutting edge possible with the right industrial blade for the specific cutting application.

The razor cutting method provides the cleanest cutting edge possible with the right industrial blade for the specific cutting application.

Sollex offers high-quality industrial slitting razor blades designed for converting and slitting common types of plastic film, including:

- Slitting Blades for PE Film

- Slitting Blades for PET Film

- Slitting Blades for PA Film

- Slitting Blades for CPP Film

- Slitting Blades for EVA Film

- Slitting Blades for PVC Film

- Slitting Blades for PI Film

- Slitting Blades for Bopp Film

- Slitting Blades for Metalized Film

- Slitting Blades for Aluminum Foil

- Slitting Blades for Laminated Films and many others.

Try Sollex Zero Friction blades: Type Z for stretched thin films without additives. For film with additives, such as white pigments, try Type K blades. A basic TiN-coated blade of type T can be used in a wide selection of applications.

PP with additives (for instance, such as calcium carbonate which makes it similar to rubber) is really tough on the blade. Cutting such film requires extreme performance and durability. Sollex V quality, such as 5V can work in cut extreme cases. Normal PP without additives should work with Sollex K and Z blades. C blades stay sharper even longer as they are self-grinding. But the C quality is also a bit fragile. Sollex X quality works if something between V and K is needed.

Most Sollex industrial razor blades are delivered in a so-called partner pack. This package is highly suitable for industrial production. The razor blades are stacked on two spears within a plastic package. The edges of the slitting blades do not come into contact with the packaging. For the user, it is easy to see how many razor blades are left because the lid on the partner pack is made of transparent plastic.

Most Sollex industrial razor blades are delivered in a so-called partner pack. This package is highly suitable for industrial production. The razor blades are stacked on two spears within a plastic package. The edges of the slitting blades do not come into contact with the packaging. For the user, it is easy to see how many razor blades are left because the lid on the partner pack is made of transparent plastic.

Order High-Quality Film Slitting Blades

Sollex has the largest stock in Europe of razor slitting blades for plastic film converting. We have all types of slitting blades, round and straight 3-hole slitting blades and injector blades in stock. Due to the variety of materials to be slit, we offer all these blades in a wide range of thicknesses, materials, edge geometries, and coatings. We offer same-day shipping on all standard industrial slitting blades from our warehouse in Malmö, Sweden. Please review our terms and conditions for ordering and delivery here.

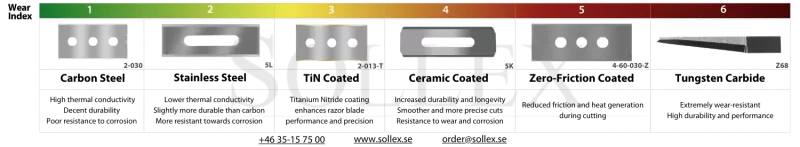

Regardless of the slitting application, we will provide you with advice and assistance in selecting the right industrial razor blade for the best cutting performance and results! Not only do we offer these blades in carbon steel, stainless steel, and tungsten carbide, but we also offer them with ceramic, titanium, and zero-friction coatings.

Our customers are leaders in the plastic and flexible packaging industries, relying on us for the right slitting blade. We value our reputation and the quality of our machine knives and blades, which is why we have been providing only quality solutions to our customers for over 98 years.

Our customers are leaders in the plastic and flexible packaging industries, relying on us for the right slitting blade. We value our reputation and the quality of our machine knives and blades, which is why we have been providing only quality solutions to our customers for over 98 years.

If you do not find the blade you need, Sollex can manufacture industrial knives and razor blades according to your drawings or to suit your needs. IIf you need any clarification about our industrial razor blades, please contact us at +4635-1575-00 or info@sollex.se.

FAQ

Q: What is plastic film slitting?

A: Plastic film slitting is a converting process where a wide parent roll of film is unwound, slit into narrower widths, and rewound onto smaller rolls using slitter-rewinders.

Q: Why are industrial razor blades commonly used for film slitting?

A: Industrial razor blades provide the cleanest possible cut for plastic films, especially thin and stretched films, resulting in smooth edges and minimal material deformation.

Q: Which types of industrial razor blades are used in film converting?

A: The most common types are slotted slitter blades, three-hole razor blades, and injector blades, each designed for specific machine setups and film properties.

Q: How do I choose the right blade thickness for slitting plastic film?

A: Thinner blades provide cleaner cuts for thin films, while thicker blades offer greater stability for higher speeds or tougher materials.

Q: What coatings are recommended for slitting stretched plastic film?

A: Zero-friction (Z) coatings are recommended for stretched films without additives, as they reduce drag and improve cut quality.

Q: Which blades are suitable for plastic films with additives?

A: Films containing pigments or mineral fillers are more abrasive and are best cut with ceramic-coated (K) or titanium-coated (T) blades for improved wear resistance.

Q: How should PP film with calcium carbonate additives be slit?

A: PP films with calcium carbonate are highly abrasive and require blades with extreme durability, such as Sollex V or X qualities.

Q: Are tungsten carbide blades used for plastic film slitting?

A: Yes. Tungsten carbide blades offer exceptional wear resistance and are suitable for demanding slitting applications, especially when long blade life is required.

Q: Can the same blade be used for different plastic film materials?

A: Some blades can be used across multiple film types, but optimal performance and blade life are achieved by matching blade material, thickness, and coating to the specific film.

Q: Why is packaging important for industrial razor blades?

A: Proper packaging prevents blade edge damage, improves safety, and allows operators to handle and count blades easily during production.

Q: Can Sollex supply custom razor blades for film slitting?

A: Yes. Sollex manufactures standard and custom industrial razor blades based on drawings or application requirements.