Challenges To Cut Plastic Stretch Film & How to Solve It

Cutting plastic stretch film is challenging because of its elasticity, cling, and additives that quickly wear blades. Without the right knives and coatings, converters face film tearing, buildup, and frequent blade changes. By using Sollex coated razor blades and proper machine setup, these challenges can be reduced while improving edge quality and productivity.

Every company that produce, store, or transport goods relies on plastic packaging. Stretch film and shrink film are important for keeping products safe and securing pallets. But they aren't the only ones. Polyethylene (PE) and polypropylene (PP) films are also commonly used for wrapping and protective covers. PVC films are used in some shrink applications. Thin cling films are used by a lot of businesses to package food or protect glass, plastic, and metal sheets during shipping.

There is one thing that all of these materials have in common: they all need to be cut at some point. Stretch film is often the hardest to work with. Because it is stretchy and sticks to things, it is hard to cut cleanly. People who work in warehouses and logistics centers know this problem all too well. A task that seems easy at first can turn out to be a waste of time, damage to goods, or even injuries.

What problems occur when cutting stretch film?

- Stretch film clings and tangles around knife blades

- Standard utility knives often tear instead of cutting

- Operators risk injuries when they apply extra force or use the wrong tool

The difficulty with stretch film lies in its structure. When pulled tight around goods, it resists the blade, and instead of being cut, it tends to stretch or tear.

Why are standard utility knives unsuitable for cutting stretch film?

Standard utility knives are rarely the right solution. They often require excessive force, and the film ends up wrapping around the blade. This situation makes the work inefficient and increases the risk of slips and deep cuts. In busy environments where speed and safety matter, these issues create unnecessary costs and hazards.

The same risks exist when cutting other packaging films: PVC and PP are tougher and may splinter, protective films cling stubbornly to surfaces, and foam films can snag or crumble if handled with the wrong knife. That is why choosing the right handheld knife is so important.

Which knives and blades are best for cutting plastic film?

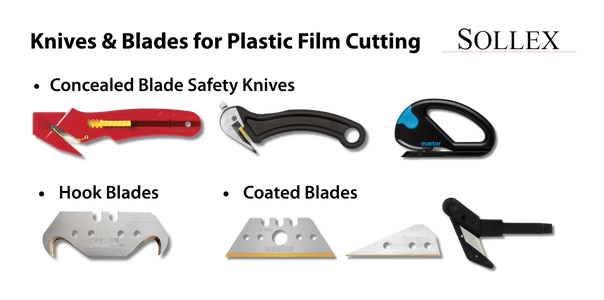

General recommendations for choosing the right knives for plastic film

For continuous cutting of stretch film, often choose safety knives with a concealed blade. Their design allows you to cut quickly and efficiently, while the cutting edge remains protected, which significantly reduces the risk of injury.

Knives with hook blades prove particularly useful when opening tightly wrapped pallets. They can cut through layers of film precisely without damaging the goods inside.

Another way to improve plastic film cutting is to use blades with an additional coating, such as titanium nitride, in the above-mentioned knife options. These coatings improve sharpness retention, reduce friction, and allow the blade to glide better when cutting difficult-to-cut materials.

Which Sollex safety knives are designed for cutting stretch film?

Sollex offers a range of professional knives specifically designed for handling films and foils. Here are four reliable safety knives that tackle the film-cutting problem head-on:

- Mure & Peyrot Bordeaux (Art. nr 1421)

- Martor Secumax Snitty (No. 43037)

- Martor Secumax Opticut 436

- Martor Secumax Opticut 437

1. Mure & Peyrot Bordeaux (Art. nr 1421)

Concealed industrial razor blade, guarded for operator safety. Designed specifically to slice thick plastic films, straps, textiles. The blade’s depth can be adjusted, and it features an anti-slip slider, plus a tip for perforating film, which is ideal for initial entry.

2. Martor Secumax Snitty (No. 43037)

Compact and lightweight, with an integrated material guide that aligns thin materials (like stretch film) toward the blade, smoothing out bumps and preventing jams. The blade is angled at 45° for effortless slicing. It offers tool‑less blade changes, four usable edges, an ambidextrous design, and a 1.9–2 mm cutting depth. Ideal for one-layer or delicate stretch film.

Built for tougher film and foam, with a Teflon‑coated metal glide foot that delivers low-friction, smooth “pull‑cut” slicing. The knife includes a bendable material guide ahead of the blade for jam prevention and is ergonomically shaped for all users. The blade is concealed for safety and easily replaceable or rotated. Excellent for heavy-duty film, its glide foot and pull‑cut design slice through film rapidly and precisely with minimal resistance.

Similar robust build as the 436, but configured for “push” cutting, giving users more control when guiding the blade through stubborn film layers. Also features a concealed blade and smooth handle design. This knife is designed for environments where operators require controlled, forward-motion slicing through thick or layered film, which enhances both accuracy and safety.

The Mure & Peyrot Bordeaux is a robust safety knife with a concealed, adjustable blade. It is built for thicker films and straps and allows operators to control the cutting depth. Thanks to its ergonomic design and safety features, it makes even stubborn film layers easier to handle. For thinner stretch films or cling films, the Martor Secumax Snitty offers an elegant solution. Its integrated material guide ensures the film slides smoothly toward the blade, resulting in a clean cut without snagging or tearing. For tougher jobs such as multilayer laminates or foam films, the Martor Secumax Opticut is available in two versions. The 436 model is designed for a pulling motion and comes with a Teflon-coated glide foot that reduces friction when working with heavy-duty or multilayer films. Its twin model, the 437, is optimized for pushing cuts, giving operators maximum control when cutting through more resistant materials.

The Mure & Peyrot Bordeaux is a robust safety knife with a concealed, adjustable blade. It is built for thicker films and straps and allows operators to control the cutting depth. Thanks to its ergonomic design and safety features, it makes even stubborn film layers easier to handle. For thinner stretch films or cling films, the Martor Secumax Snitty offers an elegant solution. Its integrated material guide ensures the film slides smoothly toward the blade, resulting in a clean cut without snagging or tearing. For tougher jobs such as multilayer laminates or foam films, the Martor Secumax Opticut is available in two versions. The 436 model is designed for a pulling motion and comes with a Teflon-coated glide foot that reduces friction when working with heavy-duty or multilayer films. Its twin model, the 437, is optimized for pushing cuts, giving operators maximum control when cutting through more resistant materials.

Scenario / Film Type | Recommended Knife | Key Advantage |

|---|---|---|

Thick, rigid film or straps | Mure & Peyrot Bordeaux | Adjustable depth & strong blade with safety guard |

Single-layer thin film | Secumax Snitty | Integrated guide & smooth slicing at 45° |

Heavy-duty multilayer film or foam | Secumax Opticut 436 | Glide foot & pull-cut ease resistance |

Requires precise forward cuts | Secumax Opticut 437 | Push-cut control on tough film layers |

What are the best techniques for cutting stretch film with handheld knives?

There are some useful skills that you need to know to cut plastic film, even if you have the right knife for the job. Cutting at an angle is one of the best ways to get better results when using a hand knife to cut any object. In this case, we're cutting plastic film. Instead of cutting through the film in a straight line, the blade slides over it better when it hits it at an angle of about 45 degrees. This lowers the resistance, makes it easier for the knife to glide, and needs the operator to put in a lot less effort.

There are some useful skills that you need to know to cut plastic film, even if you have the right knife for the job. Cutting at an angle is one of the best ways to get better results when using a hand knife to cut any object. In this case, we're cutting plastic film. Instead of cutting through the film in a straight line, the blade slides over it better when it hits it at an angle of about 45 degrees. This lowers the resistance, makes it easier for the knife to glide, and needs the operator to put in a lot less effort.

It's also important that the blade is very sharp. A sharp blade cuts smoothly, but a dull blade pulls and tears the film, which wastes material and makes it more likely that you will slip. Because of this, replacing blades on a regular basis should be a daily task in logistics and packing.

Proper knife training makes things even safer by making sure that workers know how to cut correctly, keep the film taut, and change the blades when they need to be.

When used with a good safety knife, these easy steps make work go more smoothly, hurt people less, and waste less materials.

FAQ

Q: What are the main challenges when cutting plastic stretch film?

A: Key challenges include material sticking/adhesive buildup, film elasticity causing stretch or movement, film tearing or web breaks, edge fraying or fuzz, and inconsistent blade wear (especially with filled or abrasive films).

Q: How can blade coatings help with stretch film cutting issues?

A: Coatings like TiN, ceramic, zero-friction, or low-adhesion finishes reduce friction, resist buildup of adhesive or film residue, improve edge retention, and allow for cleaner cuts with less downtime.

Q: What blade types and formats are best for plastic stretch film?

A: Thin industrial razor or round three-hole blades are good for thin, uniform stretch films; rounded or slotted blades help reduce edge damage; circular knives are better in high-speed or heavier film applications to maintain web tension and reduce variation.

Q: How do machine settings influence cut quality for stretch film?

A: Proper blade alignment, correct tension settings, minimized gap or overlap at blade/anvil (if applicable), consistent feed rate, and using sharp blades all reduce tearing, deformation, and extend blade life.

Q: What maintenance practices can reduce problems with stretch film cutting?

A: Regularly cleaning blades and anvil surfaces to remove buildup, rotating or replacing dull blades, ensuring proper lubrication where needed, inspecting for damage or wear, and scheduling preventative blade checks help maintain consistent quality and reduce scrap.