How to Use Scalpels for Precision Cutting and Detailed Work [GUIDE]

The scalpel is the perfect tool for designers, artists, and model makers for cutting materials such as cardboard, paper, wallpaper, plastic, textiles, leather, graphic design, gently deburring plastic parts and all kinds of precision cutting.

What are scalpels used for outside surgery? While most people associate scalpels with surgery, these ultra-sharp knives are also precision tools for art, crafts, model making, film trimming, and detailed industrial work. Scalpels provide clean, accurate cuts in paper, plastic, textiles, leather, vinyl, and other flexible materials. Knowing the right blade type, how to mount it safely, and when to change it is key for safe and efficient precision cutting.

Content:

- Medical scalpels and craft knives for precision cutting

- Scalpel blade types

- How to attach the scalpel blade to scalpel knife holder safely

- When is it time to change a scalpel blade?

- How to remove a used scalpel blade from a scalpel

- How to hold and pass a scalpel

- How to use a scalpel

What are scalpels and craft knives used for in non-surgical cutting?

A scalpel-like knife serves as an ideal tool for graphic designers, painters, craftsmen, artists, and model makers. A scalpel may be utilized for any creative or design task that requires precise cutting, clean edges, and fine detail work, e.g. scrapbooking, model making, stenciling, 3D modeling,etc. The primary benefit of scalpels and craft pen knives is their ability to precisely cut a wide range of flexible materials, including paper, foil, vinyl, plastic, textile, foam, rubber, felt, and leather.

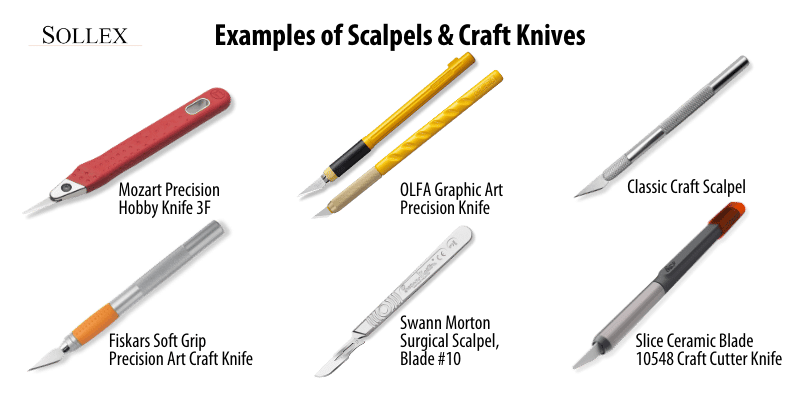

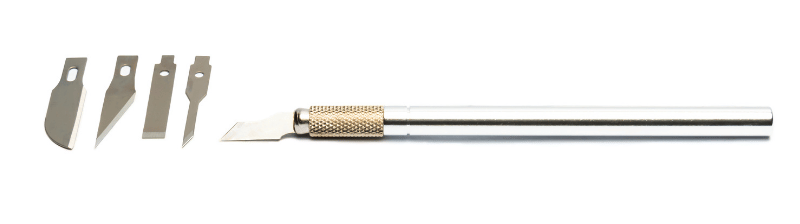

Scalpel knives come in a variety of forms, such as hobby knives, precision knives, craft knives, pen knives, and craft scalpels. Despite their different names, they all have the same construction: a plastic or metal handle on which is mounted a scalpel blade suitable for that type of scalpel.

Medical scalpels are also frequently used for fine cutting since they cut exceptionally well and maintain their sharpness longer than other types of scalpels. Compared to a regular craft knife, surgical scalpel knives provide a far cleaner cut, making it easier for the user to execute complex, precise tasks.

Which scalpel blade types are best for precision cutting?

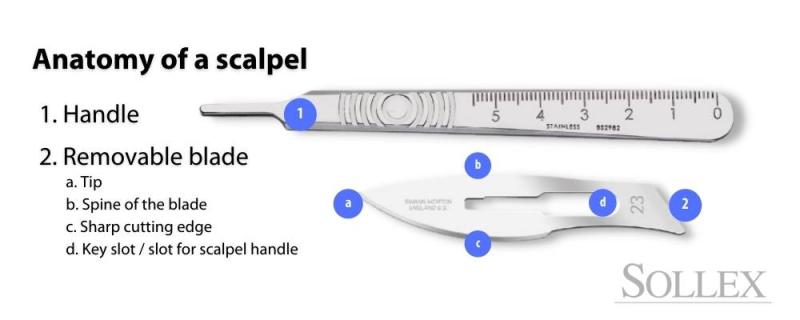

Typically, a scalpel blade is firmly fastened and composed of premium surgical or tool steel.

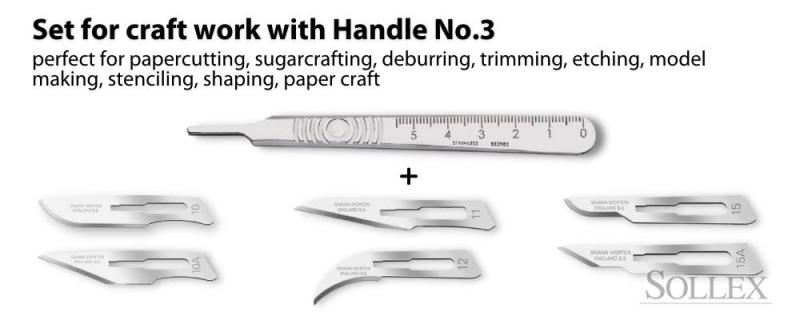

You can usually purchase a scalpel knife handle and the scalpel blade separately.

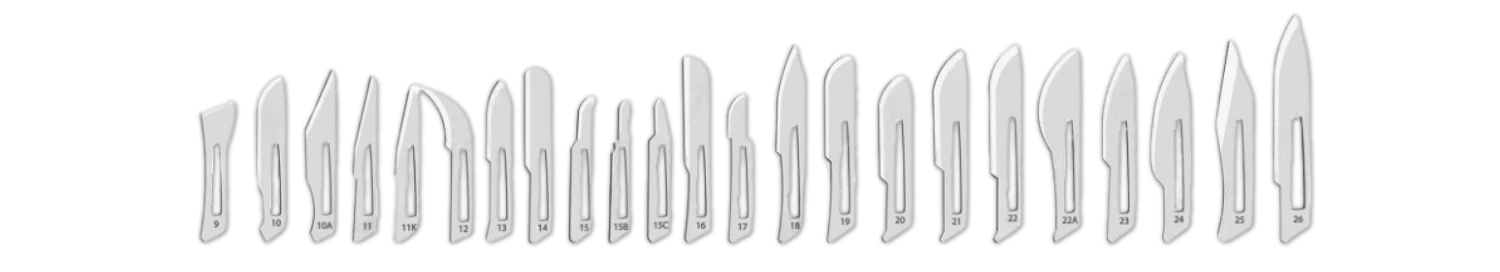

Surgical blades come in various types and shapes, each designed for a specific purpose. For example, Swann Morton’s scalpel blades of numbers 10 and 11 have a sharpened end and are ideal for very detailed work. Surgical knives are very sharp, so you must be careful and follow safety rules.

TIP: Make sure the size of the scalpel blade and handle are the same - this is especially important.

“Graphic designers use scalpel #11 blades for cutting stencils, while model makers prefer more robust craft scalpels for trimming foam board and plastic parts.”

We have blades that look and work like Swann Morton, but the ends are flat or rounded. The set includes a special non-surgical MOZART precision-cutting knife.

We have blades that look and work like Swann Morton, but the ends are flat or rounded. The set includes a special non-surgical MOZART precision-cutting knife.

The Mozart precision cutting knife 3F is more robust compared to the more commonly used medical scalpels. Use the Mozart precision cutting knife for more industrial cutting. The scalpel is very flexible and easy to use for detailed work. It is an ideal tool for cutting various materials, such as cardboard, paper, wallpaper, plastic, and textiles; gently deburring plastic parts; cutting leather; graphic design; and all kinds of precision cutting.

A special stand station for safe storage of the scalpel and additional tools is available for purchase.

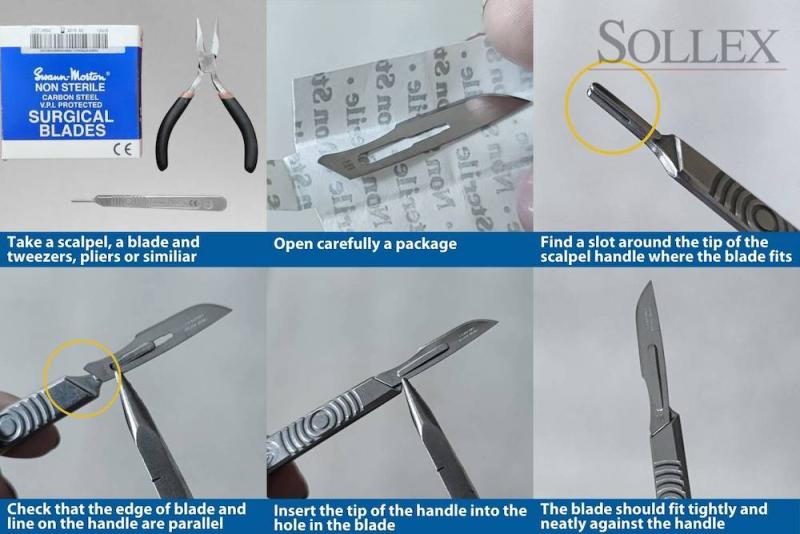

Follow these simple instructions on how to handle or attach a scalpel blade to the scalpel knife holder.

How do you attach a scalpel blade to its handle safely?

Step #1

Slide the flaps to open the scalpel packaging and remove the blade with tweezers, pliers, or similar tools. Make sure the packaging is open enough to see the slot for connecting the handle. The scalpel handle has a groove around the tip where the blade may fit. Avoid grasping the blade by its edge.

Attention! Check that the diagonal lines on the handle and blade end are parallel to ensure that the blade and scalpel holder are properly positioned. If you place the blade on the opposite side, it will catch and become difficult to remove later.

Step #2

Place the handle's tip within the blade's opening (the slot for the scalpel handle; see pic above), then push the handle forward until the blade snaps into place.

Do not use your fingers to ensure that the blade fits neatly and securely against the handle!

When should a scalpel blade be replaced?

The material, cutting method, and pressure applied to the scalpel determine how long a blade lasts. However, when you cut through something, such as a box, and hear an unusual sound, it's time to replace the blade. It is advisable to refrain from sparing the blade since a dull blade has the potential to tear the material it is cutting, leaving jagged and thoughtless cut ends.

“In hobby cutting, one blade may last for several hours of paper or vinyl work, while industrial trimming of plastics may require a change after only 15–20 minutes.”

How do you remove and dispose of a used scalpel blade?

- Grasp the blunt edge (the part of the blade without a sharp edge) of the end nearest to the handle using pliers. Turn the knife away from the hand and body.

- Lift the blade by its edge with the pliers and bend it gently, being careful not to break it. Carefully move it forward from the handle and slide it to the other side, making sure to keep people and yourself out of the path. Keeping the blade pointing downhill toward the instrument tray is crucial.

Please get rid of scalpel blades cautiously; for example, put them in a safety blade box (like the Sollex Safety box 988). It is your duty to dispose of the blade with care; do not leave it lying around the work area or somewhere else.

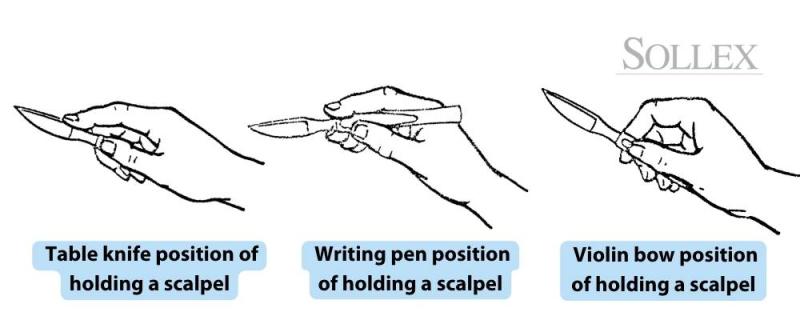

What are the safe ways to hold a scalpel?

Hold the scalpel correctly when using it. There are 3 safe ways to hold a scalpel when using it: "table knife", "writing pen", "violin bow".

The basic positions of the scalpel in the hand are the "table knife", "writing pen" and "violin bow" positions.

The thumb and middle finger tips are on the side, while the index finger is on the back of the handle when the knife is in the "table knife" position. The scalpel handle is held in the palm of your hand. This position ensures a deeper, smoother cut and more hand flexibility. Roughly speaking, the cutting angle is 90 degrees.

The scalpel is held like a pen in the "writing pen" position, with the index finger resting over the back of the handle to provide complete control. You hold the handle between your thumb, third, and fourth fingers. This enables you to adjust the cutting angle, up to 45 degrees, for example.

The scalpel is held similarly to a violin bow in the "violin bow" posture, with the thumb on one side and the other four fingers on the other. This facilitates the process of making shallow and broad cuts.

It appears that the writing pen position is best for little cuts and punctures; the table knife position offers greater pressure force and a larger cut; the bow position offers broader scope but less force.

How should scalpels be used and stored for safe cutting?

- Store the scalpel properly. Never leave a mounted blade in the scalpel, but always remove it after the job is done and put it in a safe place of storage.

- Do not drop the blade onto a rough surface, such as a metal or stone surface. The impact will damage the cutting edge and diminish the cutting performance. Do not grab the cutting edge with e.g. pliers.

- Protect yourself from dropping an extremely sharp scalpel on your lap while sitting and working at the table. You need to put something on your lap to protect you if the scalpel slides off the table.

- Do not throw the scalpel in a drawer or leave it on a table. In extreme cases, you can use, for example, a special case, work station, or cap for the scalpel blade.

- Use special cutting mats or self-healing cutting mats as a base for the material. They will improve the quality of the cut and protect the work surface. In addition, these mats have special markings and rulers that come in handy when cutting.

- Do not use gloves made of fabric that slip on the metal surface or gloves that are too thick. This can cause your finger to slip.

- Never check the blade for sharpness with your skin!

Proper transfer of the scalpel to another person is done as follows:

Put the scalpel in a napkin, like you would in a book, to prevent the person giving it from accidentally cutting their hand. Then, pass the scalpel forward, holding it by the spine with the cutting edge facing up and the blade's spine pressing against your palm.

Scalpels are not only surgical tools but versatile precision knives for creative, technical, and industrial work. With the right blade type, careful handling, and safe disposal, they deliver unmatched accuracy in cutting paper, films, textiles, plastics, and more. Sollex supplies high-quality scalpel blades and handles for professionals and hobbyists seeking clean, reliable cuts.

Sollex is a Swedish supplier of industrial knives, machine blades and various cutting tools for industries! We have cutting products featuring advanced technology and high performance, designed to enhance manufacturing and converting processes while addressing challenges. With the right knives and blades, you can get simplified maintenance, time savings, and an improved end product.

Sollex is a Swedish supplier of industrial knives, machine blades and various cutting tools for industries! We have cutting products featuring advanced technology and high performance, designed to enhance manufacturing and converting processes while addressing challenges. With the right knives and blades, you can get simplified maintenance, time savings, and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden

FAQ

Q: What are scalpels used for outside surgery?

A: Scalpels are widely used in crafts, model making, film trimming, precision cutting, and hobby work where clean, detailed cuts are required.

Q: Which scalpel blade types are most common?

A: Popular types include #10, #11, and #15 blades for detailed work, plus stronger precision blades like the Mozart 3F for industrial cutting.

Q: How do you attach a scalpel blade to a handle safely?

A: Use tweezers or pliers to slide the blade onto the handle slot until it clicks. Never use fingers to press the blade into place.

Q: When should I replace a scalpel blade?

A: Replace the blade when cuts become jagged, extra pressure is needed, or unusual sound occurs. A dull blade risks tearing materials or causing slips.

Q: How do you dispose of used scalpel blades safely?

A: Place used blades in a safety blade box (e.g., Sollex Safety Box 988) and never leave them loose in work areas or drawers.