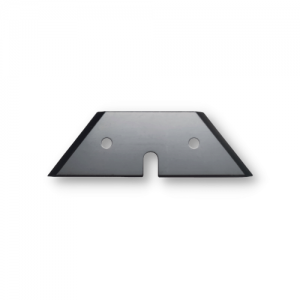

Sollex 950V Trapezoid Blade with 2 Cutting Edges

Blade design, comparing with other blades, advantages, characteristics

Martor 614 blade - a special trapezoid blade with 2 short cutting sides

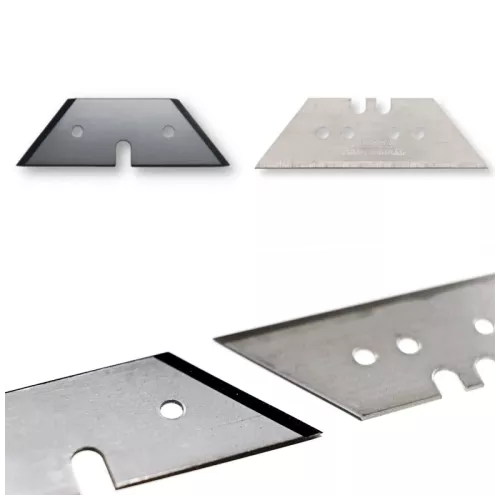

Sollex 950 or also known as Martor 614 is a trapezoid blade with grinding on the blade's short angled sides. It is a two-edged, single-sided, double-bevel blade for industrial usage. Sollex blade 950V differs from a regular trapezoid blade in that it has 2 cutting sides instead of 1 long lower sharpened side.

Given that the angle of attack of this blade is 38 degrees in relation to the material to be cut, it is ideal for cutting the material crosswise. Thanks to the blade's sturdy locking capabilities, you don't have to press it against the blade as with most other types of blades. Thus, a clear space advantage is achieved compared to conventional blades.

Given that the angle of attack of this blade is 38 degrees in relation to the material to be cut, it is ideal for cutting the material crosswise. Thanks to the blade's sturdy locking capabilities, you don't have to press it against the blade as with most other types of blades. Thus, a clear space advantage is achieved compared to conventional blades.

The cutting performance of the Sollex 950V or Martor 614 industrial packaging knives is quite specific. It does not require very high speed, but thanks to the single-sided double bevel grinding conical sharpening, you get a very fine cut, suitable for cutting off surplus material when joining rolls of material in packaging machines.

By design and performance, this trapezoidal blade works elegantly. However, for packaging knives, durability is the key issue for trouble-free maintenance. This 950V knife is also made of the highest quality tungsten carbide, ensuring a long life with high sharpness and wear resistance. The trapezoid machine knife 950V designed and most commonly used in the production of flexible and carton packaging for food and beverages.

Martor discontinues 614 and Sollex starts with 950V

The German safety knife company Martor has been producing a trapezoid knife called 614. Martor blades for packaging machines have been well known for a long time. But in 2014 this blade was discontinued by Martor for focusing on safety knives.

However, after several requests, Sollex started making the same blade to support customers who had lost their only supplier. So Sollex is the only company that still makes this high-quality Trapezoidal Blade for Industrial usage. In addition, we are the only supplier that coats Martor industrial blade no. 614 with ceramic coating for extra-long durability.

Sollex also has 752.42 and 752V trapezoidal blades, which feature a unique design with 3 sharp cutting edges. Unlike standard trapezoidal blades, which have just one long cutting edge, the 752.42 blade adds extra sharp edges on both short sides. Learn more about the 3-sided industrial trapezoid blade in an article, "High-Performance 3-Sided Cutting Trapezoid Blade".

Application of Martor 614 or Sollex 950 trapezoidal blade

This blade is typically designed to be placed in a machine to cut material webs in a transverse direction. It is not intended to cut materials in a lengthwise direction. Materials can be plastic film or paper-like materials. The special feature of this machine knife is that it has two cutting sides, allowing the material to be cut while the knife makes horizontal cuts and moves forward and backward.

Buyers of Sollex 950V or Martor 614 are machine builders or packaging manufacturing companies. It has no use outside industrial manufacturing. Customers have been Europe's largest packaging company as well as machine builders in Sweden, the Baltics, South Africa, and Germany.

How to buy trapezoidal machine blades for industrial use

Sollex is a supplier of various customer-specific blades and industrial knives. We can say that we have a lot of experience in manufacturing blades specifically for various packaging machines. The Martor 614 trapezoidal blade is an example of an industrial special-purpose blade for the packaging industry. It does an excellent job of cross-cutting the web of material.

Sollex is a supplier of various customer-specific blades and industrial knives. We can say that we have a lot of experience in manufacturing blades specifically for various packaging machines. The Martor 614 trapezoidal blade is an example of an industrial special-purpose blade for the packaging industry. It does an excellent job of cross-cutting the web of material.

If you need Custom Industrial Blades Sollex is a trusted knife blade manufacturer in Sweden. Our company was started in 1927 and we are specialized in Blades For Automated Packaging Machines. We make blades like the 950V or Martor industrial blade no. 614 for packaging machine builders and maintenance.

About Sollex Knives and Blades

Our machine knives and industrial-type razor blades are made of high-quality stainless steel with different coatings on the edge or side of the blades. Sole blades we make in solid tungsten carbide or ceramics. If you do not find the blade you are looking for, Sollex is able to manufacture industrial knives and razor blades according to your drawing or needs. You are welcome to contact us at +4635-15 75-00 or at info@sollex.se if you have any questions regarding our industrial razor blades.

About the author

Johan Falk is an expert on knives and blades and the CEO of Sollex. You can contact him directly on: 0046 708 744 786 or johan@sollex.se. For general sales questions drop an email to order@sollex.se or call us on 0046 35 15 75 00

FAQ

Q: What is the unique design feature of the Sollex 950V / Martor 614 trapezoid blade?

A: It is a special trapezoid blade with two cutting sides sharpened on the short angled sides, unlike standard blades which have only one long cutting edge.

Q: What is the primary use for the Sollex 950V packaging knife?

A: It is designed specifically for cross-cutting the material web in automated packaging machines, often used to cut off surplus material when joining rolls.

Q: Why is tungsten carbide the preferred material for the high-performance 950V blade?

A: The highest quality tungsten carbide ensures superior durability, high sharpness, and wear resistance, which is crucial for trouble-free maintenance in high-volume packaging production.

Q: What kind of cut quality does the 950V blade provide for cross-cutting?

A: Thanks to its conical, single-sided double bevel grinding, the blade provides a very fine cut, suitable for precise removal of surplus material.

Q: What is the benefit of the 950V's 38-degree angle of attack?

A: This angle is ideal for cutting material crosswise. Combined with its sturdy locking, it achieves a clear space advantage and eliminates the need to press the blade against the material.

Q: What is Sollex's unique offering for customers still using the old Martor 614 design?

A: Sollex is the only company that still manufactures this specific high-quality blade (950V) and is the only supplier that can apply a ceramic coating for extra-long durability.

Q: Which industries and companies commonly use the 950V trapezoid blade?

A: The blade is designed and commonly used in the production of flexible and carton packaging for food and beverages, and is purchased by machine builders and large packaging manufacturers.

Q: Is the Sollex 950V blade suitable for lengthwise cutting of material rolls?

A: No. The blade is typically designed to be placed in a machine specifically to cut material webs in a transverse (crosswise) direction, not in a lengthwise direction.