Choose the Right Industrial Blade

Sollex tips on how to choose the right industrial knife and what should affect the choice

Thickness performs

Thinner blades perform better. Therefore you should try to use the thinnest blade possible. A thinner blade demands less force and gives less shear in the material you are slitting. A thinner blade is helpful to avoid web breaks and gives a better cut.

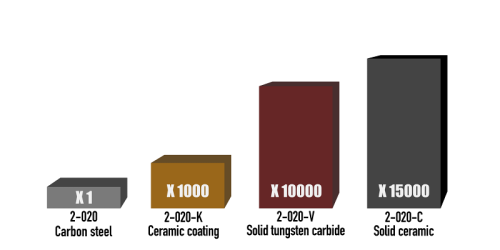

Material performs

Optimized materials increase blade lifetime. Depending on your slitting process we are able to engineer blades that will outlast and outperform wear resistant materials. Sollex makes blades in the following materials: Carbon steel, Stainless Steel (SS), Tooling steel, HSS-M2 steel, D2 steel, Tungsten Solid Carbide, Solid ceramic.

Angle performs

Most blades and materials are engineered to be positioned at a 45 degree angle to the material. Lower angles give slicing motion and spread wear out over more of the cutting surface.

Surface finish performs

A clean surface finish or cutting edge will lower the friction which reduces heat and wear. This results in cleaner edge cuts.

Edge quality performs

Multi-facet grinding and burr free edges give the best cutting results, cleaner edge cuts and reduced web breaks.

You can save money by using double sided blades where all four corners of the blade are used. Sollex reduces your costs and inventory.

Coating performs

Different coatings prolong blade lifetime and cutting quality. As an extra benefit coatings can improve surface finish and reduce friction which reduces heat and wear.

Download our catalog for manufacturers of plastic film and packaging, where you can find a more detailed table on what knife coating to choose for cutting a certain material

FAQ

Q: How do I choose the right industrial blade for my cutting application?

A: The right industrial blade is selected by balancing blade thickness, material, cutting angle, surface finish, edge quality, and coating. These factors directly affect cut quality, blade life, and production stability.

Q: Why does blade thickness matter in industrial cutting?

A: Thinner blades require less cutting force, create less shear in the material, and deliver cleaner cuts. Using the thinnest possible blade reduces web breaks and improves cutting performance.

Q: Which blade material lasts the longest?

A: Blade lifetime depends on the application. Tungsten carbide and ceramic offer the highest wear resistance, while HSS-M2 and D2 steel provide an excellent balance between durability, cost, and cutting performance.

Q: What is the best cutting angle for industrial blades?

A: Most industrial blades perform best at a 45° cutting angle. Lower angles create a slicing action that distributes wear across the edge and improves cutting efficiency.

Q: How does surface finish affect blade performance?

A: A smooth surface finish lowers friction, reduces heat buildup, minimizes wear, and produces cleaner cut edges.

Q: Why is edge quality important for cutting performance?

A: Burr-free, multi-facet ground edges deliver cleaner cuts, reduce material tearing, and minimize web breaks during slitting and converting.

Q: Can blade coatings improve cutting performance?

A: Yes. Blade coatings extend blade life, reduce friction, lower heat generation, and improve edge quality when cutting demanding or abrasive materials.

Q: How can double-sided blades reduce cutting costs?

A: Double-sided blades allow all four corners to be used, reducing blade consumption, lowering inventory costs, and improving overall cost efficiency.