Blades for Kampf Slitter Rewinder Machines

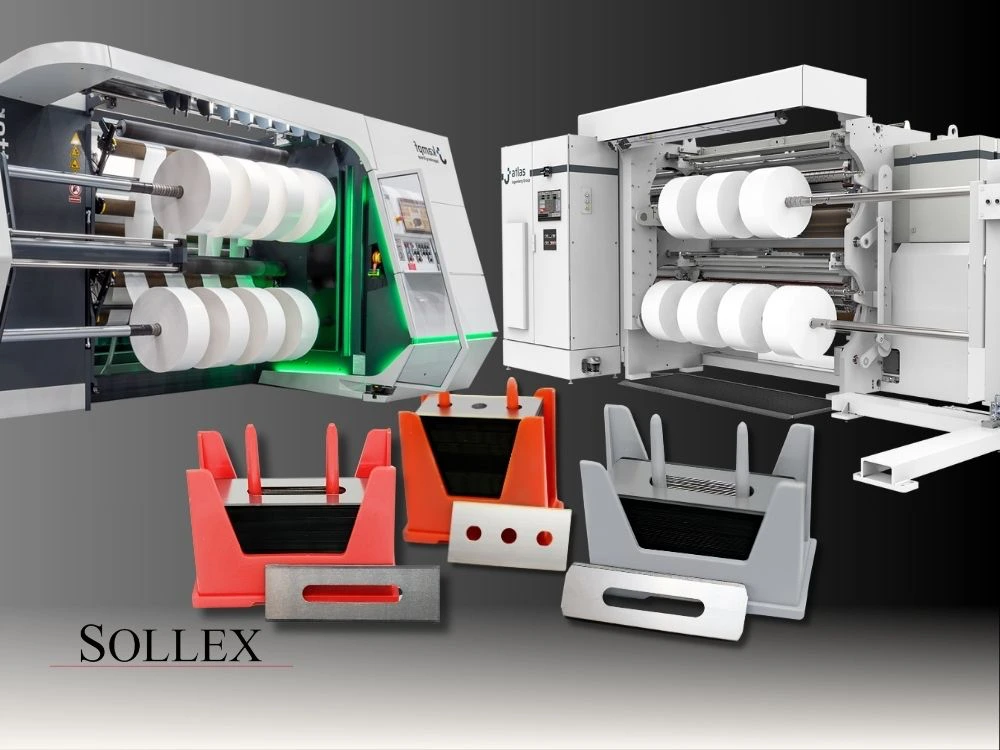

Slitting and rewinding machinery is used for the processing and converting of flexible materials and plastic film rolls. The slitter rewinders convert the material for further handling, whether for packaging, printing, or lamination. Kampf and its newly unified partner, Atlas Converting, lead this market by offering a wide range of slitter rewinder machines for flexible material manufacturers and web converters. Their industrial slitting equipment support a wide variety of materials, including LDPE, HDPE, BOPP, BOPET, BOPA, CPP, and laminated materials, positioning Kampf as a leading supplier of plastic film slitting machines and a cornerstone in flexible material processing.

What Is a Slitter Rewinder Machine?

A slitter rewinder is a machine that cuts a big roll of material into smaller rolls. The first step is to unroll the wide roll, which is called the master roll. Then, the material is carefully cut into several narrower strips. During this step, the edges are often cut to get rid of any bumps or extra material, which gives the finish a clean and precise look. After being cut and slit, each strip is then rolled back up into its own roll. This method is often used to work with materials like plastic film, paper, foil, textiles, and laminated composites. The slitter rewinder makes sure that the material is ready for the next step in manufacturing or converting by making the edges thinner and better.

Kampf PrimeSlitter Series

At the heart of Kampf's flexible film solutions is the PrimeSlitter series. Designed for high-performance slitting and winding, these machines handle primary and secondary slitting with precision and efficiency.

Model | Materials | Slitting Systems | Application |

PrimeSlitter BlackLine | BOPET, BOPP | Razor blade cut, Burst cut | High-output slitting of plastic films |

PrimeSlitter CHRO BlueLine | BOPP, BOPE, BOPET, BOPA, CPP | Razor blade cut, Burst cut, Shear cut | Medium-to-high throughput film conversion |

PrimeSlitter TF | BOPP, BOPET, BOPA, BOPLA, CPP | Razor blade cut, Burst cut, Shear cut | High-performance slitting and winding |

PrimeSlitter CHRO SilverLine | BOPP, PET, PE, PA, PLA, PS, Cast, Blown, Laminates | Razor blade cut, Burst cut, Shear cut | Flexible film and laminate processing |

Kampf / Atlas ProSlitter Series

For converters dealing with commodity films or requiring robust edge trim management, the ProSlitter range provides a reliable solution.

Model | Materials | Slitting Systems | Application |

ProSlitter BlackLine | BOPP, BOPE, BOPET | Razor blade cut in groove, Burst cut | Primary slitting of commodity films |

ProSlitter CRRO BlueLine | BOPP, BOPE, BOPET, BOPA, CPP | Razor blade cut, Burst cut | Slitting of flexible films |

ProSlitter CRRO SilverLine | BOPP, BOPET, BOPE, BOPA, PLA, PS, Laminates | Razor blade in groove, Burst in groove | Secondary slitting of biax films and laminates |

Kampf ConSlitter Series

Converters focusing on flexible packaging benefit from the ConSlitter series. These slitter rewinders manage not only films but also refined papers and laminates.

Model | Materials | Slitting Systems | Application |

ConSlitter BlackLine | Films, Refined papers, Laminates | Razor blade cut, Shear cut | Flexible packaging production |

ConSlitter CHRO / CTHO / CTRO | Films, Refined papers, Laminates | Razor blade cut, Shear cut | Versatile slitting in packaging lines |

ConSlitter BlueLine | Films, Refined papers, Laminates | Razor blade cut, Shear cut | Stable, high-speed flexible packaging slitting |

ConSlitter CFRU SilverLine | Films, Refined papers, Laminates | Razor blade cut, Shear cut | Advanced execution for packaging converters |

Kampf/ Atlas TitanSlitter Series

For operations demanding duplex slitting with high throughput and material variety, the TitanSlitter series presents a compelling option.

Model | Materials | Slitting Systems | Application |

TitanSlitter SR800 | Printed, Coated, Metallized Films, Laminates, Labels, Paper | Razor blade cut, Shear cut | Duplex slitting of specialty films |

TitanSlitter ER610-DT | Plastic Films, Laminates, Labels, Paper (10-200 µm) | Razor blade cut, Shear cut | Dual turret slitting with auto crosscutting |

TitanSlitter ER610 | Films, Refined Papers, Laminates | Shear knives, Razor slitting (air or groove) | High-performance slitting with integral edge-trim system |

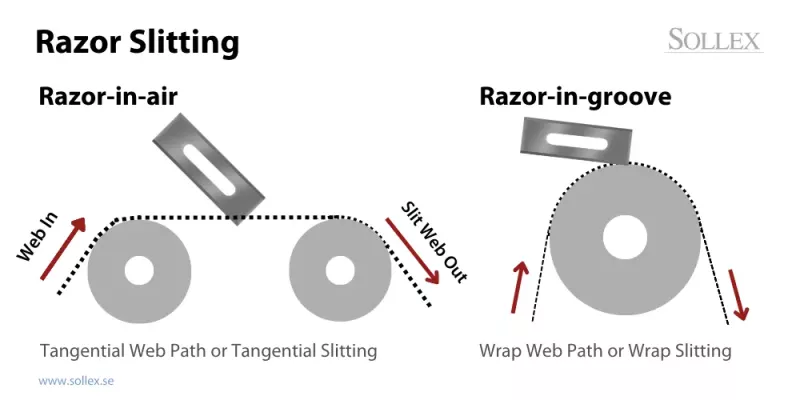

Slitting Techniques

Razor blade slitting is preferred for thin films like BOPP and BOPET due to its clean cut and minimal dust generation. Burst cutting, on the other hand, is employed when slightly thicker or more rigid films require a controlled split. Shear cutting excels in applications where laminated or multi-layered films demand strength and accuracy. Among these methods, razor slitting stands out for its simplicity and efficiency when used correctly. The precision of the slitting razor blade plays a critical role in achieving clean, consistent cuts and minimizing production waste.

Sollex Razor Blades: Recommendations for Kampf Slitting Machines

Companies that produce plastic films, flexible packaging, or laminated materials and use Kampf or Atlas slitter rewinder machines can improve their cutting quality by using Sollex slitter razor blades.

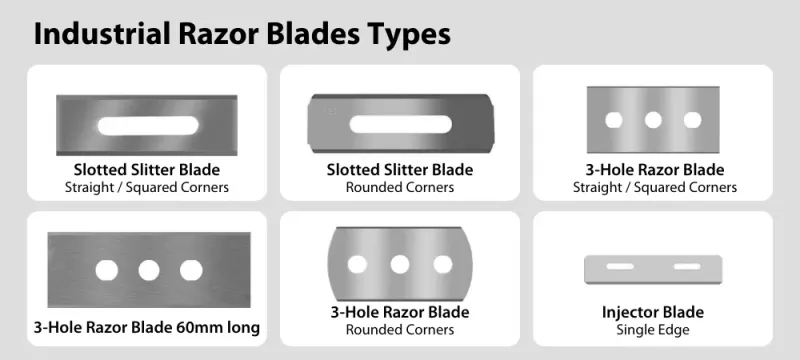

Sollex offers plastic film producers and converters, flexible packaging manufacturers, label and adhesive tape producers, lamination and coating companies, paper and foil converting companies, extrusion film manufacturers, and recycling and reprocessing plants (handling films and laminates) proven blade coatings and designs tailored for high-speed, razor-based slitting systems. Slotted razor blades such as models 5Z, 5K, and 5T are particularly suitable for film processing applications. The 5Z features a zero-friction coating and performs exceptionally well on materials like polyethylene, BOPE, PET, and PCR films. The 5K blade includes a ceramic coating that resists wear from abrasive fillers, while the titanium-coated 5T is ideal for PE and PET films, providing excellent durability.

Sollex 3-hole razor blades, including models like 2-020-Z and 2-030-Z with zero-friction coating or 2-020-K and 2-030-K with ceramic coating, are designed for precision slitting with minimal waste. These blades are thinner and highly accurate, making them suitable for printed, metallized, or laminated films. For applications involving recycled plastics or bio-derived films, thinner blades such as 2-013-K or 2-013-Z ensure razor-sharp results with reduced web deformation.

Material to cut | Blade recommendation | Key benefits |

|---|---|---|

Thin BOPP, BOPET, CPP, BOPE | Clean cuts, low dust, high throughput | |

Films with abrasive additives | 5K (slotted, ceramic coated) | Wear resistance, sharpness retention |

PE, PET, polymer films | 5T (slotted, TiN coated) | Extreme durability in long runs |

High precision, minimal waste production | 2-020-Z / 2-030-Z (3-hole zero friction) | Thinner profile, clean slit, efficiency |

Abrasive or additive-heavy films | 2-020-K / 2-030-K (3-hole ceramic) | Wear durability, razor-like cut quality |

Films with fillers or recycled content | 2-013-K / 2-013-Z | Thin-edge razor precision, reduced scrap |

In Kampf machines like the PrimeSlitter BlackLine, ProSlitter BlackLine, and TitanSlitter ER610, where razor slitting in air or groove is commonly applied, Sollex slotted and 3-hole razor blades deliver superior cut quality, fewer stoppages, and longer tool life.

By integrating Sollex razor blades, converters not only improve slitting efficiency but also achieve greater control over edge trim, tension, and product quality in flexible film conversion.

Buy Industrial Blades for Plastic Film Extrusion & Converting

Sollex AB is a Swedish company that specializes in the design, manufacturing, and distribution of industrial razor blades and cutting tools for the plastic industry. Sollex offers industrial razor blades to cut flexible plastic materials of the following types: PE, LDPE, LLDPE, HDPE, PP, BOPP, PET, PVC, EVA, bio-based and PCR recycled materials.

We offer various blade types for plastic film extrusion lines, including slotted slitter blades with rounded and straight corners, straight 3-hole blades, 3-hole slitter rewinder blades with rounded corners, coated film converting blades, and pelletizer blades for plastic recycling.

Download PDF with Sollex Blades for Plastic Industry

By selecting the right slitter rewinder configuration and pairing it with high-grade cutting tools such as Sollex blades, film producers and converters can achieve superior performance, reduced waste, and extended machine uptime. Kampf machines combined with Sollex slotted and 3-hole razor blades form a reliable foundation for precise and efficient film conversion across a broad range of applications.

Ordering Sollex industrial blades is an easy process. You can do it online on our website or contact us by mail or phone. Almost all industrial blades are usually in stock. Delivery within Sweden is 1-2 working days; to other countries, about 3-5 working days. If you do not find the slitting blade you are looking for, we can manufacture industrial blades according to your drawing.

You are welcome to contact us at +4635-15 75-00 if you have any questions regarding our industrial machine blades.

FAQ

Q: What materials are typically slit on Kampf and Atlas slitter rewinder machines?

A: Kampf and Atlas slitter rewinders are commonly used to slit plastic films such as LDPE, HDPE, BOPP, BOPET, BOPA, CPP, PLA, laminated films, metallized films, labels, paper, and flexible packaging materials.

Q: What slitting methods are used on Kampf and Atlas machines?

A: The most common slitting methods are razor blade slitting (in air or in groove), burst cutting, and shear cutting. Razor slitting is widely used for thin plastic films due to its clean cut and low dust generation.

Q: Why is razor blade quality critical on Kampf and Atlas slitter rewinders?

A: Razor blade quality directly affects cut edge cleanliness, dust formation, roll edge stability, and machine uptime. Poor blades lead to scrap, downtime, and inconsistent winding.

Q: Which Sollex razor blades are recommended for Kampf slitting machines?

A: Frequently used blades include slotted razor blades such as 5Z (zero-friction), 5K (ceramic-coated), and 5T (TiN-coated), as well as 3-hole blades like 2-020-Z, 2-030-K, and thinner 2-013 variants.

Q: What blade coatings work best for abrasive or recycled plastic films?

A: Ceramic-coated and zero-friction-coated razor blades are recommended for films with mineral fillers, additives, PCR, or bio-based content, as they reduce wear, heat, and dust.

Q: Are Sollex blades suitable for PrimeSlitter, ProSlitter, ConSlitter, and TitanSlitter series?

A: Yes. Sollex slotted and 3-hole razor blades are designed to perform reliably on Kampf and Atlas PrimeSlitter, ProSlitter, ConSlitter, and TitanSlitter machines using razor slitting systems.

Q: How do the right slitter blades improve film converting efficiency?

A: Correct blade selection improves edge quality, reduces trimming waste, extends blade life, minimizes stoppages, and allows higher and more stable production speeds.

Q: Can Sollex supply custom blades for Kampf or Atlas machines?

A: Yes. Sollex offers both standard and custom-manufactured slitter blades based on drawings or machine-specific requirements.

Q: Where can I order razor blades for Kampf and Atlas slitter rewinders?

A: Sollex supplies industrial razor blades for Kampf and Atlas machines with fast delivery. Orders and technical support are available via order@sollex.se or by phone.